Pratite promene cene putem maila

- Da bi dobijali obaveštenja o promeni cene potrebno je da kliknete Prati oglas dugme koje se nalazi na dnu svakog oglasa i unesete Vašu mail adresu.

101-125 od 189 rezultata

Prati pretragu "exit"

Vi se opustite, Gogi će Vas obavestiti kad pronađe nove oglase za tražene ključne reči.

Gogi će vas obavestiti kada pronađe nove oglase.

Režim promene aktivan!

Upravo ste u režimu promene sačuvane pretrage za frazu .

Možete da promenite frazu ili filtere i sačuvate trenutno stanje

Preis: Contact us for price Food conveying and processing equipment LIST OF EQUIPMENT 1.Incline auger conveyor (fabricated in Q4 2020) 2.Fruit declumper/breaker (fabricated in Q4 2020) 3.Metal detector shaker (metal detector head not included) (fabricated in Q4 2020) 4.Redler elevator (fabricated in Q4 2020) 5.Grading shaker with an additional set of screens (fabricated in Q4 2020) 6.Horizontal belt conveyor (fabricated in Q4 2020) 7.Redler elevator (fabricated in Q4 2020) 1. INCLINE AUGER CONVEYOR Dimensions Features Fully built in stainless steel Accumulation hopper of 1 m3 capacity made of textured stainless steel Cleaning window at the lower part of the hopper Evacuation screw of 300 mm diameter built in stainless steel Open upper side of the screw for cleaning Draining valve for cleaning Upper screens to avoid big frozen blocs Safety protections 2. FRUIT DECLUMPER/BREAKER Dimensions Features Fully built in Stainless Steel AISI-304 Grinder drums composed by Solid core Solid fingers for grinding Stainless steel sprockets Supporting box for production by means of the grinders or without grinders Stainless steel bearings Safety protections Powered by means of SEW motoreducer 3. METAL DETECTOR SHAKER (metal detector head not included) Dimensions Features Fully built in stainless steel Tray fully built-in stainless-steel plate composed by First level with screens for the single product Not single product remover area included in the first level Second level with screens to remove the small pieces and juice Juice collecting level and drainage outside the machine Second level exit for the good product made in PE blue to pass trough the metal detector Vibration by means of fibber springs working at high frequency Reaction mass in 5 mm stainless steel plate Isolation by means of rubber silent blocks Chassis in stainless steel structural profile for the required working height Powered by-mass motor-vibrators (OLI trademark) Supported over columns 4. REDLER ELEVATOR Dimensions Upper horizontal track: 1.800 mm Lower horizontal track: 1.900 mm Height of charge: 600 mm Height of discharge: 3.850 mm Width of blades: 500 mm Inclination: 60 º Features Built of stainless steel AISI 304. Thickness of the bottom plate 4mm (electro-polished) Stainless steel dragging conveyor belt on deslidur guide with Z-18 sprocket. URTASUN certified chain Blue polythene pusher blades Driven by SEW motor gearbox Auto tension system Anti-return system Stainless steel bearings with Stainless steel housing Protection safety stainless steel round bars Manual cleaning gate (easy sliding) placed in the lower horizontal track Diagonal exit 5. GRADING SHAKER WITH SET OF SCREENS Dimensions Sizes: 3 sizes + 1 over sizes = 4 sizes Features Fully built in stainless steel Tray fully built-in stainless-steel plate composed by 6 grading screens of 600x800mm with easy adjustment. 50 mm step between each set of 2 size’s screens. Note additional set of 27 screens is included in the offer Size collecting hopper for every 2 screens to collect in total 3 sizes Connecting chute between hopper and downstream equipment Exit of oversize by the front of the shaker Connecting chute from front exit to a container for oversize Vibration by means of fiber springs working at high frequency Reaction mass in 5 mm stainless steel plate Isolation by means of rubber silent blocks Chassis in stainless steel structural profile for the required working height Powered by-mass motor-vibrators (OLI trademark) Supported over columns Power supply: 2 Kw 6. HORIZONTAL BELT CONVEYOR Dimensions Features Fully built in Stainless Steel AISI-304 Belt Intralox thermoplastic and modular material Traction by thermoplastic sprockets Retaining sides Floating scraper for cleaning of the belt Driven by pendular SEW motor gearbox Back lock and motor gearbox cover Side protections placed in transmission zones to avoid risk of entrapment Stainless Steel bearings 7. REDLER ELEVATOR Dimensions Upper horizontal track: 1.300 mm Lower horizontal track: 1.700 mm Height of charge: 600 mm Height of discharge: 2.600 mm Width of blades: 500 mm Inclination: 60 º Features Built of stainless steel AISI 304. Thickness of the bottom plate 4mm (electro-polished) Stainless steel dragging conveyor belt on deslidur guide with Z-18 sprocket. URTASUN certified chain Blue polythene pusher blades Driven by SEW motor gearbox Auto tension system Anti-return system Stainless steel bearings with Stainless steel housing Protection safety stainless steel round bars Manual cleaning gate (easy sliding) placed in the lower horizontal track Find more here pokazati kontakte Contact us at pokazati kontakte Poruka Poruka

Description Used Bottle Labeler Krones Starmodul 12000 bph year 2003 Builder: Krones Model: Starmodul (960-16, K405004) Year of construction: 2003 Hourly production / bottles per hour: 12000 BPH Direction of rotation: Counterclockwise Size type: 1 l (glass) Product: Oil Number of targets: 16 Number of stations: 2 (1 cold glue module – 1 adhesive module, could still accommodate 1) Type of labeling: self-adhesive + cold glue Number of labels: 2 (165×110 paper) Manuals available: Yes Machinery still in operation: No (stopped since December 2016) Photo: OK Availability: immediate Speed: 12000 BPH Containers: Glass Formats: 1.0 L No. of plates: 16 Plate movement: Mechanical cam brake/clutch Number of stations: 2 Rotation direction: Counterclockwise Labeling method: Adhesive, Cold glue Label adjustment: N/A Container orientation method: Mechanical Head adjustment: N/A Add. label smoothing at machine exit: Yes Safety features: Yes Manuals: Yes stato: In storage Poruka Poruka

STAHL KH-78/82 - FFH flat feeder - 1 station, entrance width 78 cm, 4 cassettes with sheet passage control, photocell at entry and exit from the station, combined cassettes. - Knife transverse folds in the KTL system, 2 knives + side cassette parallel to the 1st knife, safety kit, soundproof covers, EMV filter, safety devices. - Enhancement kit for knife assembly, control panel with display, electronic preparation mode, optimization of sheet spacing, improved sheet passage control. - Comfort set for the knife assembly in the KTL system, external adjustment of the knife inclination, knife height, precise setting of side stops and transport rollers. - A device for kneading, perforating and cutting into folded knife shafts. - Device for punching perforation for knife shafts after the 1st knife bend, including a separate switch - Device for kneading, perforating and cutting after the 1st knife fracture. - Delivery of the VSA-66, 2006 - max format 78x128cm, min format 14x18cm. Poruka Poruka

Marke: H&H Herzog & Heymann, MBO Flat pile feeder MBO F 76 Solo with independent drive for max. format of 72 x 102 cm built 2011 from MBO are designed specifically for use in workplace environments that have frequently changing finishing requi-rements Because these machine are independently controlled they can be quickly integrated inline with a variety of other finishing modules as new configurations are needed Technical Exit height adjustable up to 950mm Format (Width x Length) min.105 x 170 mm Format (Width x Length) max.720 x 1020 mm Maximum pile height 660 mm VACUSTAR Head Mechanical Double Sheet Stop Independent self-controlled Control MBO MS-Control Cutting unit H&H N 381 with Technifold Creasing tools built 2011 Combined right angle-/side-lay for right angle receipt ofthe product and exactalignment insidefollowing side-lay 3 pair of shafts Poruka Poruka

Make: Stafa Model: Drill Note: - Borermotor til 18-30 ton gravemaskine / Powerfull drill for 18-30 ton excavator Year: 1992 Year is estimated and non-binding: Yes Hours approx.: Unknown Weight kg approx.: 0 To machine size ton: 18-30 Is visually reviewed, but not fully tested in all functions: Yes Visual condition (1-5) 5=best: 3 Technical condition (1-5) 5=best: 3 Categories: Construction Equipment & Attachments , Attachments Powerful earth boring machine for 18-30 ton excavator - can pull drill bits with 1.5m Ø diameter and 12 m depth. Dimension of the drilling machine: Height 1.3m x Diameter 0.70m and the base plate under the drilling motor is 0.9m Ø. Comes with 3-claw coupling for drilling (picture of 3-claw is for illustration). NB: Sold without drill and without drill rods. NB: The gasket at the exit to the drills is leaking and should be replaced!!! See more pictures and information - as well as other auctions at pokazati kontakte Stafa Drill - Borermotor til 18-30 ton gravemaskine / Powerfull drill for 18-30 ton excavator Poruka

Description Used Case packing Monoblock brand Oma YOM 1996 – 2005 bph Monoblock Oma Brand components: Case erector with single-head packer It can make a case of 6 or a case of 12 bottles. Safeguards. Painted iron frame. There are various formats. Manufacturing year of the case packing triblock 1996. Production is about 450 cases per hour of 6 bottles. There is no taping machine at the output of the case packing tri-block to seal the upper and, lower part of the case. Thus, motors must be used on case exit belts. The case can then go to the taping machine to be closed from the bottom and top. The taping machine must have a flap system; that foresees the pre-folding of the upper flaps to carry out a correct closure of the case. On request, we can create a correct layout customized to the needs of the buyer. Speed: 2500 BPH Containers: Glass Formats: 0.75 L No. of sockets: 1 Closure: Adhesive tape Head type: Fixed Entrance: Straight Safety features: Yes Manuals: Yes stato: Ready for operation Poruka Poruka

Description Used Labeler Krones Topmatic Krones labeling machine model topmatic from 1992 capable of reaching speeds of 40.000 bph. The machine has all its safety protections and also the machine manuals with all the maintenance documents. The labeler is currently disassembled and mothballed. The rotation direction is counterclockwise and the number of stations is 3. This labeler handles only cylindrical bottles. This used labeler is in excellent condition, well-kept, and is sold with some of its spare parts. Standard feed type with two exit lanes. The direction of movement is from right to left, then counterclockwise. Labeling machine used for the labeling of champagne bottles. Labeling is possible at 3 stations, only hot glue. Integrated label control with light sensor. Various label formats are possible: Staniol in the neck area back label Neck loop and label torso Speed: 40000 BPH Containers: Glass Formats: 0.20 L No. of plates: 45 Plate movement: Mechanical cams Number of stations: 3 Rotation direction: Counterclockwise Labeling method: Hot glue Label adjustment: Auto Head adjustment: Manual Safety features: Yes Manuals: Yes stato: In storage Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

AIR CONDITIONER AM FM RADIO AUXILIARY HYDRAULICS BOOM CHECK VALVE BOOM, 1 PIECE CE PLATE COUPLER, HYDRAULIC ENGINE ENCLOSURES HAND AND FOOT CONTROL LIGHTING Online Owner's Manual PILOT CONTROL PRODUCT LINK ROCK DRILL ARRANGEMENT RUBBER TRACK STICK CHECK VALVE STICK, SHORT ULTRA LOW SULFUR DIESEL FUELGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Car Body: Good Counterweight: Good Eng. Enclose Hood / Stack: Good Fuel Tank: Good Grab Irons: Good Main Frame Welds: Good Radiator Grill & Shroud: Good SAFETY ITEMS: Cab Guards: Yes ROPS: Yes Brake Hold: Good Horn: Good Secondary Exit: Good Swing Brake: Good GAUGES, OPERATOR STATION, CONSOLE: Back Up Alarm: No ROPS Certification Plate: Yes Air Conditioner: Good Dash Console: Good Door Latches: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good BOOM: Boom Condition: Fair Boom Pins: Fair Pins & Bushings - BOOM: Fair STICK: Stick Length: BRAS DE 1.67 m Pins & Bushings - STICK: Fair Stick Conditions: Fair Stick Pins: Fair : FINAL DRIVES: Housings: Good Planetaries / Diff: Good COMMENTS, MISC. REPAIRS, GENERAL REMARKS: comment 1: FR-24 Poruka Poruka

THERMAL OIL HEATER, 1.000.000kCal/h Main Features: Capacity: 1.000.000kCal/h Width: 2.320mm Height: 2.330mm (with chimney 5.465mm) Length: 4.945mm (w/o burner and chimney 3330mm [+/-50mm]) Maximum operating temperature: 230°C Coil type: Coaxial double-line with double pipe Heating coil pipe: Ø 60,3 x 3,6mm DIN 2448 seamless steel Heating coil total surface area: 50m² Heater body: t = 8mm, 19 Mn 6, DIN EN 10028-2 Isolation plate thickness: 0,8mm, roll aluminum. Isolation material thickness: 50mm, 80kg/m³ rock-wool Burner: BALTUR Gas burner TBL 150 P, w/ multiblock. Oil circulation pump: 65/200 ALLWEILER, 15kW, NTT series hot oil circulation pump. Hot oil valves: DN80 & DN100, PN16 bellow type globe valves. Oil strainer: DN100, PN16. Degasser: Included Flanges: DN80, PN16 oil pressure & lines. DN32 degassing line. Electrical components: All major components are Eaton (ex-Moeller). Digital controllers are Jumo. Safety equipment: Danfoss differential pressure switch to ensure oil circulation, no.2 thermocouple and no.2 double contact temperature controller for oil inlet & exit temperatures. Safety relief valve for hot oil line. No.2 Pekkan monometer. Expansion tank: 400lt elevated expansion tank. Glass tube level indicator and indicator valves. Elevating tower and piping is included. Poruka Poruka

| Depalletizer | TMG | VEGA 60 | 2004 | For empty bottles | Filling Monoblock | Procomac | 56 8 8 141 | 2004 | | Capping Machine | Bertolaso | EMN 550/350 | 1995 | | CIP | Procomac | 92.003.657 | 2004 | | CONVEYORS | Procomac | | | Until the exit of the triblock | Labeling Machine | Kosme | EXTRA ADHESIVE 720 12T S3 E3 CE | 2006 | | Case Erector | TMG | ORION | 2008 | | Case Sealer | TMG | TM90S | 2004 | Description Used Filling Line for Sparkling Wine PROCOMAC Up to 6000 BPH Condition and Capacity Firstly, the filling line reaches up to 6000 bottles per hour (BPH), standing as an efficient solution for companies aiming to optimize their bottling processes. Currently stored, moreover, this line offers versatility in handling different glass container formats, specifically 0.375 L, 0.75 L, and 1.5 L, for both sparkling and still wines. Additionally, the isobaric filling technology ensures product integrity throughout the process. Key Components of the Used filling line for sparkling wine PROCOMAC up to 9000 bph The system comprises several key machines. Initially, the TMG depalletizer, model VEGA 60 from 2004, handles empty bottles. Following this, the Procomac filling monoblock, model 56 8 8 141 from 2004, integrates filling stages into a compact solution. Furthermore, the Bertolaso capping machine, model EMN 550/350 from 1995, ensures each bottle is sealed correctly. Cleaning and Maintenance Essential for maintaining quality and hygiene, moreover, the Procomac CIP (Cleaning-In-Place) system, model 92.003.657 from 2004, allows for effective and automated cleaning of the equipment without disassembly. This aspect is crucial to ensure the longevity and efficiency of the filling line. Automation and Labelin g Moreover, automation plays a key role in the line’s efficiency. Conveyors move bottles from the depalletizer to the exit of the triblock, highlighting the importance of uninterrupted workflow. Subsequently, the Kosme labeling machine, model EXTRA ADHESIVE 720 12T S3 E3 CE from 2006, applies labels accurately, ensuring a consistent and professional brand image on the final product. Packaging Final packaging is managed by TMG machinery: the ORION case erector from 2008 prepares cardboard cases, while the TM90S case sealer from 2004 closes and seals the cases, ready for distribution. These final steps are vital to ensure that the finished product is presented and protected adequately for transport. Performance of the Used filling line for sparkling wine PROCOMAC up to 9000 bph Lastly, the line displays versatility in performance, with a nominal speed of 6,000 BPH for sparkling wine in the 0.75 L format and 9,000 BPH for still wine in the same format. This flexibility demonstrates the adaptability of the used PROCOMAC sparkling wine filling line to different production needs, making it a valuable solution for any winery. Speed: 6000 BPH Containers: Glass Formats: 0.375 L, 0.75 L, 1.5 L Product: Wine (Sparkling), Wine (Still) Fill type: Isobaric Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

THERMAL OIL HEATER, 500.000kCal/h Main Features: Capacity: 500.000kCal/h Width: 1.695mm Height: 1.865mm (with chimney 5.200mm) Length: 4.075mm (w/o burner and chimney 2800mm [+/-50mm]) Maximum operating temperature: 230°C Coil type: Coaxial double-line with double pipe Heating coil pipe: Ø 48,3 x 3,6mm EN 10216-2 P235 GH TCI seamless steel Heating coil total surface area: 25m² Heater body: t = 8mm, 19 Mn 6 (or 17 Mn 5), DIN EN 10028-2 Isolation plate thickness: 0,8mm, roll aluminum Isolation material thickness: 50mm, 80kg/m³ rock-wool Burner: BALTUR diesel burner TBL 150 P Oil circulation pump: 40/200 ALLWEILER, 7,5kW NTT series hot oil circulation pump. Hot oil valves: DN62, PN16 bellow type globe valves. Oil strainer: DN65, PN16. Degasser: Included Flanges: DN65, PN16 oil pressure & lines. DN32 degassing line. Electrical components: All major components are Eaton (ex-Moeller). Digital controllers are Jumo. Safety equipment: Danfoss differential pressure switch to ensure oil circulation, no.2 thermocouple and no.2 double contact temperature controller for oil inlet & exit temperatures. Safety relief valve for hot oil line. No.2 Pakken monometers. Expansion tank: 400lt elevated expansion tank. Glass tube level indicator and indicator valves. Elevating tower and piping is included. Poruka Poruka

JJ Broch clasif-4sorting machine for garlic A consistent size improves the crop profit. The modular grader JJ Broch can be adapted for number of sizes needed PRECISE SORTING The long length of any hole belt unit and the separate belt speed provide enough time for an exact grading of the bulbs in its precise size. RUBBER HOLE BELTS - Belt 40 mm - Belt 50 mm - Belt 60 mm CAREFUL GRADING AND EXIT The transfer belts are positioned at a very low drop height to avoid damage in bulbs. Can unload to Big boxes or small boxes. HIGH ENTRY VOLUME An effective working width of 1000 mm ensures a high volume flow of garlic bulbs up to 8 T m per hour. More information or a quote? Do this quick and easily via the Duijndam Machines website! You can also give us a call. See all the available machines at our website. - Since 1977 supplier of reliable used agricultural and horticultural equipment - Machines are checked for delivery - Experienced team - We can help you with getting the machine to your company Duijndam Machines The specialist in used agriculture and horticulture machinery = More information = Year of manufacture: 2018 General condition: good Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Anti-theft System Arrangement - Mass Excavator Auto Lube Boom - 1 Piece Boom Check Valve CE Plate Lighting Mirrors Online Owner's Manual Product Link Radio - Bluetooth Stick - Short Stick Check Valve Straight Travel Pedal Ultra Low Sulfur Diesel Fuel: SAFETY ITEMS: Cab Guards: Yes ROPS: Yes Safety Decals In Place: Yes Safety Decals Legible: Yes Fire Extinguisher: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good : ENGINE: Blow By: No Knocking: No Oil Leaks: No Water in Oil: No Belts / Pulleys: Good Fuel Injection System: Good Governor: Good Turbocharger / Blower: Good COOLING SYSTEM: Compression in Radiator: No Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Block Heater: No Ether Aid: Yes Alternator: Good Batteries / Cables: Good Lighting: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Motors: Good Tank: Good Travel Motors: Good : STICK: Stick Length: 3 M Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: (Fair) BUCKET: Quick Coupler: No Width: 185 CM Bucket Bottom: Good Bucket Linkage: Good Bucket Mounts: Good Bucket Sides: Good Teeth / Adapters: (Good) FINAL DRIVES: Housings: Good : Poruka Poruka

Description Used rotary adhesive labeling machine PE Universal 16T up to 6000 bph In the bottling industry, the efficiency and precision that the “Used Adhesive Rotary Labeler PE Universal 16T” brings to the production line are paramount. Introduced by P.E. Labellers, this rotary adhesive labeling machine known by its model number UNIVERSAL 16T-1120-4S-4E, was launched in 2005 and has since established its reliability and performance consistency, notably handling up to 6000 bottles per hour (bph). Sophisticated Design & Capacity Constructed for glass containers, particularly with formats supporting 1.0 L, the robust design reflects its capacity to sustain high-volume production workflows. With its 16 plates functionality, the rotary adhesive labeling machine ensures uniform application and distribution of work, a technical detail that resonates well with experts seeking minimal downtime and maximum throughput. The machine’s efficiency is further highlighted by its counterclockwise rotation direction, an engineering choice facilitating seamless integration with standard production line flows. This directionality is critical for maintaining consistent operational rhythms, minimizing disruptions during the bottle labeling process. Technical Precision in Labeling Diving deeper into its technicalities, the “Used Adhesive Rotary Labeler PE Universal” employs adhesive and hot glue labeling methods. These techniques are celebrated for their steadfastness, ensuring labels adhere flawlessly even under high-speed conditions. Automatic label adjustment is a pivotal feature, allowing for real-time modifications and ensuring each label is perfectly positioned, responding dynamically to on-line demands without the need for manual intervention. Furthermore, the mechanical container orientation method showcases the machine’s technical prowess, guaranteeing the precise alignment of bottles, critical for uniform label application. Operational Safety and Current Condition Safety cannot be an afterthought in high-speed production environments. Acknowledging this, the rotary adhesive labeling machine comes equipped with essential safety features, meeting industry standards and ensuring operator safety. Currently in storage, the machine is well-maintained, promising not only safety but also reliability and efficiency for future operations. In addition to the machine’s technical specifications, its manual head adjustment provides an extra layer of operational control. This feature, coupled with additional label smoothing at the machine’s exit, emphasizes the model’s attention to detail, contributing to its esteemed standing in settings that demand precision. Concluding with its current state, this model, though launched in 2005, is far from being obsolete. Its presence in storage indicates a readiness to be reintegrated into production lines, backed by its comprehensive manuals ensuring ease of reassembly and operation. This comprehensive insight into the rotary adhesive labeling machine underlines its capacity, design, and precision, aspects that technicians and industry experts genuinely appreciate. Integrating the SEO keyword seamlessly ensures the content remains engaging while promoting visibility among targeted professional audiences. Adhesive rotary labeler machine P.E. Labellers Universal Master 16T-1120-4S-4E This adhesive labeler has the following special elements: – Three adhesive groups and one glue group with 16 heads and a pitch of 1120 mm – It could reach higher speeds if the type of adhesive groups are changed, replacing the existing ones with higher speed adhesive stations this also intends to change the encoders of the used labeler. – Have to be upgrade the electrical system too in that case. The machine has always been maintained correctly. It may only be necessary to carry out replacement of seals and bearings as a precaution. Upon request, it is also possible to carry out a revision in our workshops. The cams for the movement of the plates are mechanical, therefore are in an oil bath. It can also be modified upon request to create an electronic cam with the addition of optical centering. It is also possible to apply wrap-around labels by modifying the central cam for moving the plates. This is a counter-clock wise adhesive labeler with label ironing system at the machine exit. This used rotary labeler can work square bottles just like other brands like Kosme, Krones, Sacmi, Makro and Z Italia. This 2005 labeler has one used bottle size equipment for 1 liter round bottles. It requires around 25 square meters for the working space. Speed: 6000 BPH Containers: Glass Formats: 1.0 L No. of plates: 16 Plate movement: N/A Number of stations: 4 Rotation direction: Counterclockwise Labeling method: Adhesive, Hot glue Label adjustment: Auto Container orientation method: Mechanical Head adjustment: Manual Add. label smoothing at machine exit: Yes Safety features: Yes Manuals: Yes marca: P.E. Labellers stato: In storage Poruka Poruka

Description Used Filling Monoblock Alfatek Easy Compact 2018 MONOBLOCK Mod. ROBOT COMPACT 7/1 Machine suitable for treating refermented beer in the bottle. Machine suitable for treating Steinie Flasche 0.33 I bottles Height 174mm — diameter 70mm Composition: • Elvira LP Series filler with 7 filling valves • Single-head crown capper Mod. “Eagle/C” Max. production: 500/1000 bph with 330 cc bottles and product without foam. Production may vary according to the type of product to be bottled. Power supply: 380V three-phase * N — 50hz • Electrical panel position: Right • Control panel nameplate language: Italian Worktop: 1000 + -50 • Bottle entry and exit: on the right Bottle size: • Height: from 174 to 310 rams. Diameter: 58 to 110mm. • Bottle neck diameter: from 16 mm (int.) to 30 mm (ext.) Level variation in the bottle: from 40 min to 75 mm Bottle neck height: H. level + 30 min The Used Filling Monoblock Alfatek Easy Compact can only be unloaded with a forklift of adequate capacity and forks of no less than 1,400 mm in length. Complete with safety guards in accordance with CE standards. ACCESSORIES INCLUDED IN THE PRICE: CE-rated safety guards; Equipment for n. 1 cylindrical bottle format; Towing head. return head, bottle arrival table. Speed: 1000 BPH Containers: Glass Formats: 0.33 L Product: Alcohol, Beer No. of valves: 7 Fill type: Gravity/light depression Type of nozzle: Fixed Safety features: Yes Manuals: Yes Rotation direction: Clockwise stato: Ready for operation Poruka Poruka

This 3-axis OKUMA LB2000 EXII MYC lathe was manufactured in 2018. It features a max machinable diameter of 360mm and a workpiece length of 250mm. The machine offers internal cooling through the spindle, a V12 VDI design revolver head, and a 6” chuck. Equipped with the OSP-P300L CNC Controller and advanced features like the Machining Navi L-g for vibration dampening and OKUMA Virus Protection System. Consider buying the OKUMA LB2000 EXII MYC machine we have for sale. Contact us for further details. application type: Turning Location: Hungary machine type: Lathe availability: Immediately GINDUMAC ID: HU-TUR-OKU-2018-00002 Spindle speed range: 45-6000 rpm 1/MIN Spindle bore: Ø62 mm Number of axis: 3 X-AXIS Movement: 260 mm Y-AXIS Movement: 100 mm (+/-50) Z-AXIS Movement: 350 mm Number of stations: 12 Type of tool holder: VDI design Chip conveyor: Yes Spindle nose: jis a2-6- Max. Turning diameter: 360mm- Max. Turning length: 250mm- Internal cooling through spindle machining navi l-g for vibration dampening api library 2 for industry 4. 0 okuma virus protection system Poruka Poruka

Description Modular labeling machine 14 heads cold glue – adhesive 8000/14.000 BPH: This New modular labeling machine can be customized as needed. Suitable for applying labels: COLD GLUE AND ADHESIVES • GLUE collar • GLUE back • “U” or “L” seal • ADHESIVE front • ADHESIVE back Bottles-Containers: CYLINDRICAL and SHAPED No. labeling stations: No. 3 COLD GLUE groups N. 2 adhesive groups 60 meters ON THE MODULAR TRAY Head diameter Ø: Ø 960 mm Plates number: 14 Min/max label length: 10/150 Min/max label height: 15/200 Container diameter/height min/max: Ø 30/80 mm – Height 100/400 mm Max required speed: 8,000 bph Basic machine composition 1. System built according to CE regulations 2. Machine operation via PLC (Schneider) 3. Touch-screen control panel for labeler functions installed on a mobile and rotating support 4. Automatic variation of production speed with inverters and detection sensors installed on the conveyor belts 5. Light column indicating the operating status of the labeler 6. Electrical cabinet fixed internally to the machine body. 7. Accident prevention protections consisting of: On the screw front, with two swing doors On the labeling station front, single-body circulars a vertical lift 8. Height-adjustable upper head in the Modular labeling machine for different containers with gearmotor, panel adjustment, and automatic stop limit switch. 9. Plate rotation via electronic cams 10. Shaped plates 11. The transmission between the plate and the motor occurs via a maintenance-free gear reducer 12. Quick plate change 13. Body of plates removable from the lower carousel (complete with all their transmission) 14. Cochlea with a stop in phase Adhesive stations: 15. N. 2 adhesive labeling stations ON THE MODULAR TRAY, including: Stepper motor The machine stopped after two labels were missing on the reel Memory for 200 different labels Automatic missing label recovery function 4-axis adjustment system, without tools Reel exhaustion sensor Standard photocell for non-transparent labels 16. U-shaped or L-shaped sealing pliers with 7 DIVISIONS Cold glue station: 17. N.3 Cold glue labeling station, type: Norm 4-4-120, including: Motorization with servomotor Automatic glue film adjustment Automatic washing of the drum tweezers for label removal. Glue pump Forced oil lubrication No greasing points Radial and tangential adjustment with machine in production 18. REMOTE ASSISTANCE Plastic part for the entry of bottles: 19. Modular labeling machine equipped with: N.1 Equipment for CYLINDRICAL container format consisting of: Nr. 1 container introduction screws with UNIVERSAL container shape FOR BOTTLE DIAMETERS FROM 60 TO 120 MM Nr. 1 entry/exit star Nr. 1 central container guide Nr. 14 clay targets 20. N. 4 Smoothing station for labels 21. N.1 Cold glue label equipment N. 1 Label warehouse N. 1 set of label-picking pallets; N. 1 label picking pliers drum; N.1 Label smoothing station. 22. N.1 Equipment for cold glue labeling N. 1 Label warehouse N. 1 set of label-picking pallets; N. 1 label picking pliers drum; N.1 Label smoothing station. 23. N.1 Cold glue “L” seal equipment N. 1 Label warehouse N. 1 set of label-picking pallets; N. 1 label picking pliers drum; N.1 set of pads and hands for the seal pliers. OPTIONAL 1. CHANGE OF CYLINDRICAL BOTTLE FORMAT: • Nr. 1 entry/exit star • Nr. 1 central container guide • Nr. 14 shaped plates • Nr. 1 ironing set 2. Label equipment • N. 1 label warehouse • N. 1 set of label-picking pallets; • N. 1 label picking pliers drum; • N.1 label smoothing station. 3. Nr. 1 UNIVERSAL inlet/outlet star WITH LITTLE HANDS CAPABLE OF WORKING BOTTLES WITH DIAMETERS MIN 54 MAX 116 OPTIONAL ACCESSORIES: 1. Motorization of the conveyor belt complete with motor reducer, drive head, idle return head, chain, and motor control 2. (alternative) only conveyor belt motor control with inverter (gear motor, towing head, idle head and chain supplied by you) 3. Rotating labeled container collection plate, diameter 800 mm, completely made of AISI 304 stainless steel 4. Rotating labeled container collection plate diameter 1200 mm completely made of AISI 304 stainless steel 5. Supplement price for transformer voltage different from standard (400V (± 10%) 50 Hz 3PH + earth + Neutral) 6. Main electrical panel with air conditioner in case of factory temperatures above 35°C 7. Paper stop sensor for transparent polypropylene labels (cost for each single labeling station) on the pack lab adhesive station 8. Ionizer for transparent polypropylene labels to eliminate electrostatic charges (cost for each single labeling station) 9. Optical centering 10. Free passage of containers if the labeler is not used 11. UPS panel data backup in the event of a power failure both for the central part and pack lab adhesive station 12. Control of bottle falling at machine entrance 13. List of essential spare parts 14. List of spare parts for 2000 working hours 15. List of spare parts for 4000 working hours 16. Supplement price for the main electrical panel inside the machine in AISI 304 stainless steel (replacement with standard painted steel) 17. Arrangement to insert INK-JET encoder on a carousel with adjustable support and encoder (encoder supplied by you) 18. Mechanical thermal transfer encoder mod. BARBAN CX30 (printing area 20×30) installation on the self-adhesive labeling station to print production batches complete with first production start-up spare parts and adjustable support 19. Control of label presence only on the container with photocells to detect the label at the machine exit, complete with acoustic and luminous alarm and machine stop after a number of repeated errors (for 03 labels) 20. Glue unit height adjustment Standard parameters of the Modular labeling machine: Supporting and upper structure in hot-dip galvanized steel Top and side cover in AISI 304 Container transfer The spacer screw, the input/output stars, and the central guide are made of wear-resistant synthetic material. The lateral and belt sliding guides are made of plastic Carousel The container locking heads have a height tolerance of up to 15 mm PLATE HANDLING: ELECTRONIC CAM pack lab adhesive station: Self-adhesive labeling station The pack lab adhesive station was created in modules independent of each other and fixed on a modular aluminum profile – Paper unwinder – Label peeling blade – Drive roller – Support paper rewinder – Electrical panel with quick connections. Each individual group can be quickly and easily replaced. The pack lab adhesive station or glue station is fixed to a solid mechanical structure, equipped with 4 adjustment axes, complete with format position indicators. The technique of the Modular labeling machine 14 heads cold glue – adhesive 8000 bph The label drive motor is perfectly synchronized with the speed of the labeler detected and controlled by a single high-resolution encoder. The label dispensing speed based on the pack lab adhesive station is variable. By stopping the machine during labeling with the label dispensed halfway, it is possible to restart without having defects in the application of the label on the container. The paper drive roller is specifically treated so as not to stick The machine stops after two labels are missing on the reel. Automatic missing label recovery function. Smoothing The smoothing, customized for each individual format, includes brushes and/or rollers that can be removed as a whole for replacement without the use of tools. For certain applications, an additional smoothing device can be mounted on the belt. Transmission and main control The transmission to all moving parts is given by alternating gears in C40 and Zellamid steel. The central motorization of the Modular labeling machine is provided by a gear motor driven by an “Inverter” electronic frequency converter. Speed regulation and automatic control The production speed of the machine is totally automatic and is variable based on the incoming flow and outgoing disposal of the containers. Furthermore, a stop device, installed at the machine entrance, guarantees a minimum accumulation of containers at the machine entrance and an automatic safety stop in the event of an accumulation of containers at the machine exit. Everything is managed by a PLC. Pneumatic system Service group incorporated into the Modular labeling machine with regulation valve and water separating filter ready for an existing connection. Electrical installation CE-compliant system, ready for connection to the network. Voltage according to customer specifications. Control voltage 24 V DC Maintenance Manual, individual, and grouped greasing points. Low-maintenance materials are used on the panel, such as sealed ball bearings and self-lubricating sliding materials. Periodic check of the oil level in the spacer screw. Speed: 8000 BPH Containers: Glass No. of plates: 14 Plate movement: Electronic cam stepper/stepper motor Number of stations: 5 Rotation direction: Clockwise Labeling method: Adhesive, Cold glue Label adjustment: Auto Head adjustment: Electric Add. label smoothing at machine exit: Yes Safety features: Yes Manuals: Yes Poruka Poruka

Description Used Shrink Wrapper GIEMME model VEGA VE 20R91R – year 2016 Vega lines work with centering of the print on the bundle with even higher performance and speed. These lines include the latest mechanics, new generation PLCs, wide flexibility of use as well as rapid and precise format change. It has the possibility of packaging products of small or medium dimensions on double or triple tracks. Suitable for a wide variety of product types, whether made from glass, plastic, cardboard or metal. Some technical specifications: To meet the various requirements the following have been created for the machine: Channeling units for rectangular or square shaped products b ox overlay feeders, bundle overlay clusters, c onveyor belts and roller conveyors on the exit of the bundler. The main purpose of this type of machinery is to make the multipack, this corresponds to packs of 6 bottles closed in a cardboard and then gathered in a bundle of 4 packs. Multipack format is widely used by companies because it guarantees the consumer the protection of the bottles. The entrance of the machine can be straight or at 90 degrees with respect to the main driving axis of the cartons. This type of input can depend both on the layout of the production line or on the speed of the bundler. Speed: 20 Bundles/minute Formats: 0.275 L Film type: Neutral Tray: Not available Machine feed type: 90 degrees Bundles per minute: 20 Safety features: Yes Manuals: Yes Measurements: L: 6300 mm W: 2100 mm marca: GIEMME stato: Ready for operation Poruka Poruka

It consists of three independent elevators controlled by servo motors, to introduce and extract the parts from the bath, along with a series of functionalities to fully cover the customer's cleaning and automation needs. Customized ultrasonic cleaning solution -Three independent elevators controlled by servo motors. -Air blow drying system at the exit of the tanks. -Automatic detergent dosing system using venturi effect. -Oil removal system. -Particle filtering system. -Vapor collection system per tank. -Control panel with alarm system and color beacon. -Automatic emptying system. Automatic detergent dispenser The detergent dosing is done automatically through a dosing system that, during the automatic filling, takes the required amount of detergent and mixes it with water. To supply the dosing system, the detergent collector must be placed in a detergent drum. The collector has a level detector to warn when the drum runs out of detergent. The collector tube must reach the bottom of the drum for effective level detection. The warning will appear on the bottom of the machine's control panel screen Filtering system The bag filter operates on the principle of microfiltration. The liquid is purified in interchangeable bags by passing through small permeable pores and can be used for large amounts of water. The liquid flows from the top of the filter housing and is evenly distributed among the bag. The liquid exits from the bottom leaving behind the dirt. As the bag is enclosed in the top of the container, all the dirt is trapped inside the bag. The filter container does not require cleaning after use. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

AM FM RADIO ULTRA LOW SULFUR DIESEL FUEL BEACON BOOM CHECK VALVE CARBODY, STANDARD PRODUCT LINK CE PLATE UNDERCARRIAGE, LONG HAND AND FOOT CONTROL AUXILIARY HYDRAULICS COUPLER, HYDRAULIC STICK CHECK VALVE LIGHTING BOOM, 1 PIECE ROCK DRILL ARRANGEMENT AIR CONDITIONER STICK, MEDIUM: SAFETY ITEMS: Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Horn: Good Secondary Exit: Good Swing Brake: Good : ENGINE: Blow By: No Compression in Radiator: No EPA Decal: No Fluid Levels OK?: Yes Knocking: No Oil Leaks: Yes Water in Oil: No Air Cleaners: Good Belts / Pulleys: Good Engine Supports: Good Exhaust / Muffler: Good Fuel Injection System: Good Governor: Good Oil Filter Condition (CUT): Good Operating Condition - ENGINE: Good Turbocharger / Blower: Good COOLING SYSTEM: Leaks: No Notes - COOLING SYSTEM: Niveau ELC trop haut Coolers: Good Fan: Good Fan Drive: Good Hoses: Good Radiator: Good Water Pump: Good : HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Filter Condition (CUT): Good Hose Lines: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Travel Motors: Good BOOM: Boom Length (Actual Length): 6.9m Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Stick Length: 3.4m Pins & Bushings - STICK: (Fair) Stick Conditions: Good Stick Pins: Good BUCKET: Quick Coupler: (Yes) Brand: Strikland Quick Coupler (Make/Model): Hydraulique Geith Width: 1850mm Bucket Bottom: Good Bucket Linkage: (Fair) Bucket Mounts: (Fair) Bucket Sides: Good Cutting Edges: Good Teeth / Adapters: Good : FINAL DRIVES: Housings: Good Planetaries / Diff: Good : Poruka Poruka

Length of the Kronen GS10: 1610 mm Height: 1275 mm Feeding height: 777 mm Discharge/exit height: 470 mm Belt width: 125 mm Bottom bracket height: 130 mm Conveyor speed: 2.2-16.4 m/min Theoretical cutting thickness: 1-130mm full power: 1,8 kW Tension: 230 V N/PE Frequency: 50Hz Quantity in Stock: 3 Length: 3 meters Weight: 235kg Width: 670 mm KRONEN GS10 vegetable preparation and cutting line. Line consisting of a KRONEN brand cutting machine, model GS10, from the year 2003 with two stainless steel support benches with nylon tops; Stainless steel washing tank from the KRONEN brand. The GS10 is the ultimate multi-purpose belt cutting machine for salads, lettuces, vegetables, fruits, herbs, meats, fish, sausages, breads, cheeses, nuts and more. It is ideal for use in large kitchens, catering and industrial applications. The GS10 features a compelling package of innovative features and enhancements, such as: - inclined surfaces - modern hygienic design - completely redesigned downholder - new safety interlock system on the knife box The GS10-2 is equipped with a 125mm wide conveyor belt with perfect support technique for correct and smooth product guidance. Various cutting accessories for a wide range of applications are available:- - slice delicate salad leaves and herbs like chives, dill and parsley - strip cutting/dicing/segmenting vegetables/fruits etc. - grate/shred raw vegetables, cheese, bread/nuts, etc. - shred all types of cooked meats (chicken, beef, pork) and sausages It is a stainless steel machine for the most demanding jobs - offering precise, quality cuts. Poruka Poruka

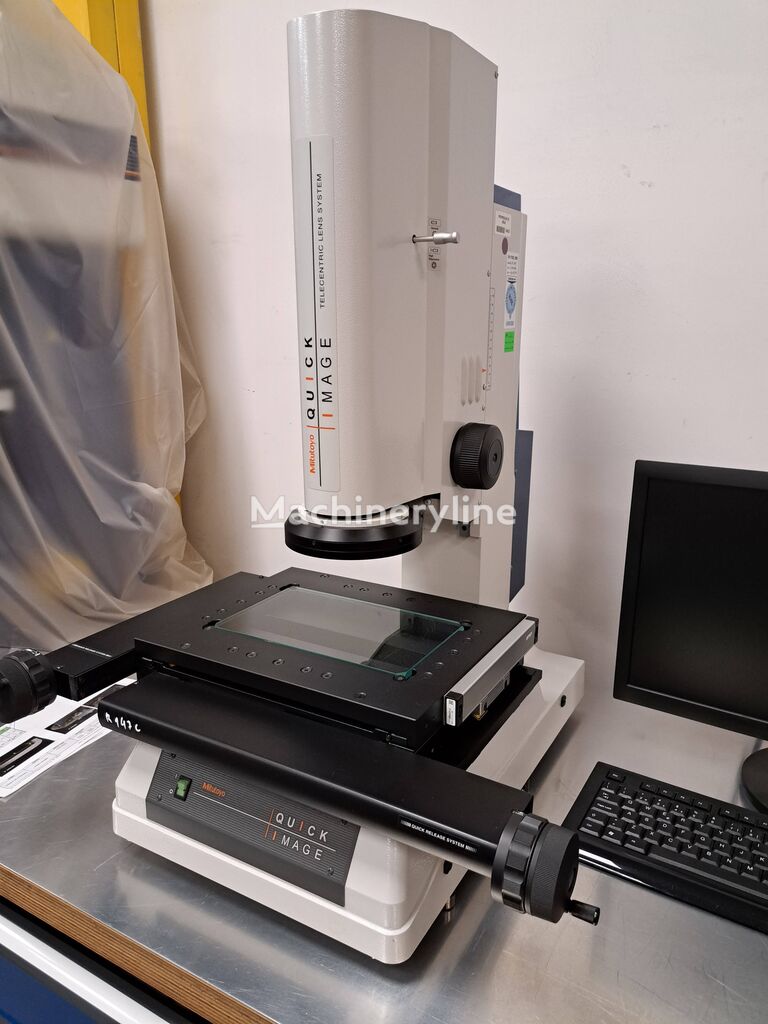

Cable length: 3 meters Accuracy (20°C): (3+3L0/1000)μm Exit sign: Double sine wave with 90° shift Maximum response speed: 50m/min output signal step: 20μm scale reference point: 50mm steps Protection Level: IP53 compatible counter: KA counter / KLD200 counter Cabinet Support 23": Optional 4-5th axis ready: Yes Rotative desk: two-axis Nikken Table dimensions: 30" x 70" Load capacity: 2000 lbs. main engine: 15 hp spindle speeds: 60-8000 rpm conical tool: CAT-40 profile lighting: Pattern Operating Temperature: 0 to 45°C tool stations: 21 X axis measurement: 210mm Measurement Interval: 0 - 972mm Effective stroke L0 (mm): 120 (4.5") No. of memorized programs: 50 programs (max.) digital resolution: 0.0001/0.001/0.01/0.1 mm or 0.000001/0.00001/0.0001/0.001" stack autonomy: approx. 5 hours measuring force: 1N Imperial-Metric: Metric/Inch Z axis measurement: 420mm cone iso: 40/50 Tension: 230 V skate course: 600 mm Precision Rotary Lathe: Optional Block Number: 1 iris diaphragm: Optional Cabinet Support 32": Optional Accumulated height (µm): 10 Precision Fixed Lathe: Optional Perpendicularity: 5 µm (after compensation) Repeatability: (2σ) Flat Air Cushion: yes, full/semi-floating Compensation method: counter balance machine dimensions: 1.50x0.55x1.70m Screen Diameter (in.): 16 " Screen diameter (mm): 400 Motorized X-Y Axis: Optional CNC control: Optional Focus range (in): 2" Focus range (mm): 50 Weight: 24 Kg Work Internship (in.): 21.25" x 5" Working phase (mm): 540 x 130 control: CNCFanuc 18i-M CNC Control Angular measurement resolution: 1 minute Surface Lighting: Pattern Control system/software: QC100/200/5200, M2, M3 optical edge detection: optional System Type: Upper Workbench MITUTOYO Quick Image AT112-120F measuring system. Poruka Poruka