Pratite promene cene putem maila

- Da bi dobijali obaveštenja o promeni cene potrebno je da kliknete Prati oglas dugme koje se nalazi na dnu svakog oglasa i unesete Vašu mail adresu.

126-150 od 198 rezultata

Prati pretragu "exit"

Vi se opustite, Gogi će Vas obavestiti kad pronađe nove oglase za tražene ključne reči.

Gogi će vas obavestiti kada pronađe nove oglase.

Režim promene aktivan!

Upravo ste u režimu promene sačuvane pretrage za frazu .

Možete da promenite frazu ili filtere i sačuvate trenutno stanje

-

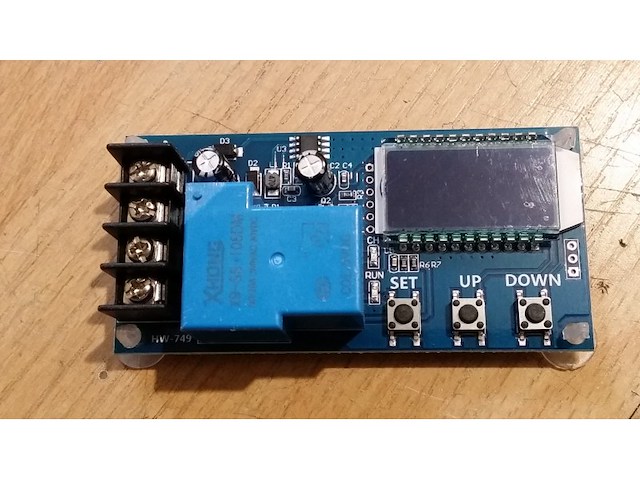

Mašine i alati chevron_right Ručni alat i rezervni delovi

P01 1. Support Lead-acid battery and Acting Battery,voltage range:6V~60V; 2. Can display voltage,percent of battery,charging time at the same time through LCD; 3. The function is very powerful,realizes the automatic charge control, the control charge time, also may set up and uploads the corresponding parameter through the serial port; Function description 1. Automatic Charge control function: By setting the volt-HI:`UP` volt-LI:`dn`;When the battery voltage is below the volt-LI:`dn`,the relay leads,the charger begins to charge the battery;when the battery voltage is up to volt-HI:`UP`,the relay is diconnected and the automatic charge is completed once; 2. Charge Time Control Function: How to turn on the time control function? After entering the parameter set, set the parameter op is non-zero, then turn on the time control function, op default parameter is:--:--h, the default does not turn on time control function; After the opening Time control function (OP is non-zero), when the battery voltage is the lower volt-LI`dn`, the charger began to charge the battery, the system began to clock; During the timing, the battery voltage ≥ volt-HI`UP`, relay disconnect; If the OP time is up, the battery voltage is still the lower volt-LI`dn`, the relay keeps the conduction, automatically closes the charge time control function, and flashes the H:ER to remind the user, the time parameter setting is unreasonable; Press any key to stop flashing; Note: Time format: 00:59 (00 for hours, 59 for minutes) The maximum time is 99:59, which is 100 hours. 3. Serial data upload and parameter setting function: The system supports UART data upload and parameter setting UART:115200,8,1 Cmd Func on Relays enable to open off Relays disable to open start Start data upload stop Stop data upload read Read the param setting dw10.0 Set volt-LI:`dn` up20.0 Set volt-HI:`UP` xx:xx Set the charge time OP 00:00 stop charge time Data Upload message Format: Battery voltage + battery percent + charge time + charge status 12.0V,020%,00:10,OP Parameter Setting a) Press and hold the SET key to enter the setting interface; b) Switch the parameters you want to set by short press SET; c) After the selection of parameters, can be set by the UP/DOWN key to support the short press, long press (fast increase or decrease); To set other parameters, repeat step b, c); d) After all parameters are set, long press set key to exit and save; The Key Function Description: In the Run interface (main interface): Short press SET button to display the current set of parameters; Short press UP button, toggle display charge percentage and charging time; Short Press DOWN button, select Turn on/off relay enabling, if the relay can be closed, will show ` off ` as a reminder; Long press UP button, switch low power state on:No operation in 10 minutes turn off backlight OFF: Backlight is always bright Long press SET button,enter the parameter settings. Calculation of voltage percentage: voltage percentage = battery voltage/(volt-HI – volt-LI) Additional Features a) Charging time recording function: not open charging time control, the product will record a full time, when the entry time display interface, flashing display charging time, and then exit time display interface or next charge to open (relay conduction) when empty; b) Automatic parameter detection: When the parameters are set, exit, if volt-LI dn≥ volt-HI UP, the system will flash display `ERR` as a reminder; c) Battery Access detection: This product attached to the battery, if not connected to the battery, the system will be shown in the downlink `NbE` as a reminder Analysis of common failures Q: How much is suitable for V level use? How much v voltage does this module fit? A: This section is suitable for the minimum 6V, the highest 60V voltage range, the maximum expenditure level 48V, because 48V battery full of electricity in 60V, and then a high fever, if your battery is higher than 48V, please select other section. Q: The power of the subsequent electrical appliances snapped! LED flashing? A: This is because your charging current is too large or the battery capacity is too small to cause a power to immediately reach the voltage limit, relay disconnect, disconnect, the voltage and quickly down to the lower voltage, and began to recharge, cycle, at this time you want to reduce the charging current only line, Usually the charging current is the battery capacity of the very 1 to 1.5, such as 20AH battery charging current generally around 2-3a! Note that a large current charge will cause the battery fever accelerated aging, drum kits and even explosions! Q: What control mode? Can I cycle the charge automatically? Can I use the side charge? Can I limit the flow? A: This is voltage control, For example, set the voltage limit of 12.0V, voltage up to 14.5V, voltage charge to 14.5V this value on the power off, voltage down to the 12.0V relay closed and start charging, can be filled with side, voltage control mode only to turn off and open, can not limit the flow, charging current completely depends on your charger! Q: Input 12V can or not charge 24V battery, or enter 48V can give 12V battery charge? A:This is a simple voltage controller, only play the role of switch, can not swing to the battery charge, so you want to give what battery charge to be ready what kind of charger! It`s necessary!

-

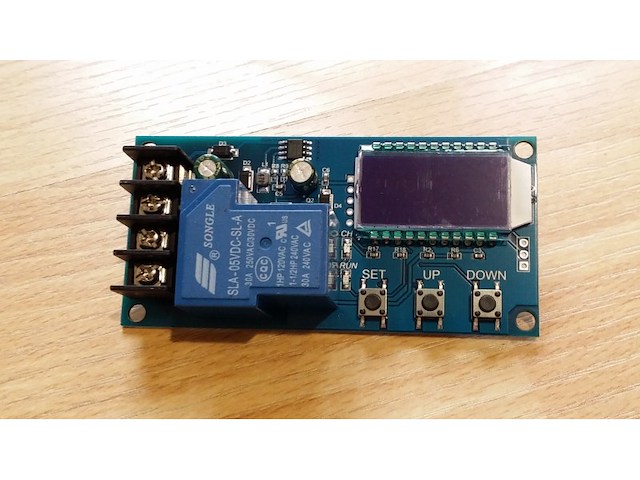

Mašine i alati chevron_right Ručni alat i rezervni delovi

P12 1. Support Lead-acid battery and Acting Battery,voltage range:6V~60V; 2. Can display voltage,percent of battery,charging time at the same time through LCD; 3. The function is very powerful,realizes the automatic charge control, the control charge time, also may set up and uploads the corresponding parameter through the serial port; Function description 1. Automatic Charge control function: By setting the volt-HI:`UP` volt-LI:`dn`;When the battery voltage is below the volt-LI:`dn`,the relay leads,the charger begins to charge the battery;when the battery voltage is up to volt-HI:`UP`,the relay is diconnected and the automatic charge is completed once; 2. Charge Time Control Function: How to turn on the time control function? After entering the parameter set, set the parameter op is non-zero, then turn on the time control function, op default parameter is:--:--h, the default does not turn on time control function; After the opening Time control function (OP is non-zero), when the battery voltage is the lower volt-LI`dn`, the charger began to charge the battery, the system began to clock; During the timing, the battery voltage ≥ volt-HI`UP`, relay disconnect; If the OP time is up, the battery voltage is still the lower volt-LI`dn`, the relay keeps the conduction, automatically closes the charge time control function, and flashes the H:ER to remind the user, the time parameter setting is unreasonable; Press any key to stop flashing; Note: Time format: 00:59 (00 for hours, 59 for minutes) The maximum time is 99:59, which is 100 hours. 3. Serial data upload and parameter setting function: The system supports UART data upload and parameter setting UART:115200,8,1 Cmd Func on Relays enable to open off Relays disable to open start Start data upload stop Stop data upload read Read the param setting dw10.0 Set volt-LI:`dn` up20.0 Set volt-HI:`UP` xx:xx Set the charge time OP 00:00 stop charge time Data Upload message Format: Battery voltage + battery percent + charge time + charge status 12.0V,020%,00:10,OP Parameter Setting a) Press and hold the SET key to enter the setting interface; b) Switch the parameters you want to set by short press SET; c) After the selection of parameters, can be set by the UP/DOWN key to support the short press, long press (fast increase or decrease); To set other parameters, repeat step b, c); d) After all parameters are set, long press set key to exit and save; The Key Function Description: In the Run interface (main interface): Short press SET button to display the current set of parameters; Short press UP button, toggle display charge percentage and charging time; Short Press DOWN button, select Turn on/off relay enabling, if the relay can be closed, will show ` off ` as a reminder; Long press UP button, switch low power state on:No operation in 10 minutes turn off backlight OFF: Backlight is always bright Long press SET button,enter the parameter settings. Calculation of voltage percentage: voltage percentage = battery voltage/(volt-HI – volt-LI) Additional Features a) Charging time recording function: not open charging time control, the product will record a full time, when the entry time display interface, flashing display charging time, and then exit time display interface or next charge to open (relay conduction) when empty; b) Automatic parameter detection: When the parameters are set, exit, if volt-LI dn≥ volt-HI UP, the system will flash display `ERR` as a reminder; c) Battery Access detection: This product attached to the battery, if not connected to the battery, the system will be shown in the downlink `NbE` as a reminder Analysis of common failures Q: How much is suitable for V level use? How much v voltage does this module fit? A: This section is suitable for the minimum 6V, the highest 60V voltage range, the maximum expenditure level 48V, because 48V battery full of electricity in 60V, and then a high fever, if your battery is higher than 48V, please select other section. Q: The power of the subsequent electrical appliances snapped! LED flashing? A: This is because your charging current is too large or the battery capacity is too small to cause a power to immediately reach the voltage limit, relay disconnect, disconnect, the voltage and quickly down to the lower voltage, and began to recharge, cycle, at this time you want to reduce the charging current only line, Usually the charging current is the battery capacity of the very 1 to 1.5, such as 20AH battery charging current generally around 2-3a! Note that a large current charge will cause the battery fever accelerated aging, drum kits and even explosions! Q: What control mode? Can I cycle the charge automatically? Can I use the side charge? Can I limit the flow? A: This is voltage control, For example, set the voltage limit of 12.0V, voltage up to 14.5V, voltage charge to 14.5V this value on the power off, voltage down to the 12.0V relay closed and start charging, can be filled with side, voltage control mode only to turn off and open, can not limit the flow, charging current completely depends on your charger! Q: Input 12V can or not charge 24V battery, or enter 48V can give 12V battery charge? A:This is a simple voltage controller, only play the role of switch, can not swing to the battery charge, so you want to give what battery charge to be ready what kind of charger! It`s necessary!

-

Mašine i alati chevron_right Ručni alat i rezervni delovi

P16 Xy-t01 digital temperature controller high precision digital display temperature controller module refrigeration and heating Product functions: 1. Heating mode `H`: When the detection temperature ≤ the set temperature - return difference temperature, the relay is turned on and the heating equipment starts to work; When the detection temperature is ≥ the set temperature, the relay is disconnected and the heating equipment stops working; 2. Refrigeration mode `C`: When the detection temperature is ≥ the set temperature + return difference temperature, the relay is turned on and the refrigeration equipment starts to work; When the detection temperature is less than or equal to the set temperature, the relay is disconnected and the refrigeration equipment stops working; 3. High temperature alarm function ala: When the actual temperature is greater than or equal to the alarm temperature, the system will start the audible and visual alarm, disconnect the relay, and press any key to stop the audible and visual alarm; 4. Delayed start of OPH: After completing a normal heating or cooling work, the system starts to count T. only when t ≥ OPH, the system can carry out the next round of heating or cooling work; 5. Temperature correction function ofe (- 10.0 ~ 10.0 ℃): If the system works for a long time, there may be deviation. Through this function, the actual temperature = measured temperature + calibrated value; 6. Remote reading / setting of parameters: Start temperature, stop temperature, temperature correction and other parameters can be set through UART; 7. Real time temperature reporting: If the temperature reporting function is enabled, the product will transmit the detected temperature to the terminal through UART at an interval of 1s for data acquisition; 8. Relay enable (default on): If the relay is turned off and enabled, the relay remains disconnected; 9. Restore factory settings: Press stop and set for more than 3S at the same time to restore the factory setting; Operating mode / setting temperature / return difference temperature setting: 1. In the operation interface, briefly press the set key to enter the quick setting interface; 2. Press the temperature setting / difference key to enter the working mode setting interface (short time setting); 3. Use the up down key to modify the parameter value, and support short press / long press; 4. Press and hold set for more than 3S or for 6S without any key operation, exit the quick setting interface and save the parameters; Alarm temperature / delay start setting / temperature correction: 1. In the operation interface, long press set for more than 3S to enter the parameter setting interface; 2. After entering the parameter setting interface, briefly press the set key to switch the parameters to be set (alarm temperature / delayed start setting / temperature correction); 3. Use the up down key to modify the parameter value, and support short press / long press; 4. Press and hold set for more than 3S or for 6S without any key operation, exit the parameter setting interface and save the parameters; How to turn on high temperature alarm (off by default): Enter the parameter setting interface, switch to the alarm parameter ala interface, and turn on or off the high temperature alarm function by short pressing the stop key; If the high temperature alarm function is off, ALA displays` ---- `as a reminder; How to turn on delayed start (off by default): Enter the parameter setting interface, switch to the alarm parameter OPH interface, and turn on or off the high temperature alarm function by short pressing the stop key; If the high temperature alarm function is off, OPH displays` ---- `as a reminder; Serial port control (single chip microcomputer TTL level communication) Communication standard: 9600bps data bit: 8 Stop bit: 1 Check bit: None Flow control: None

-

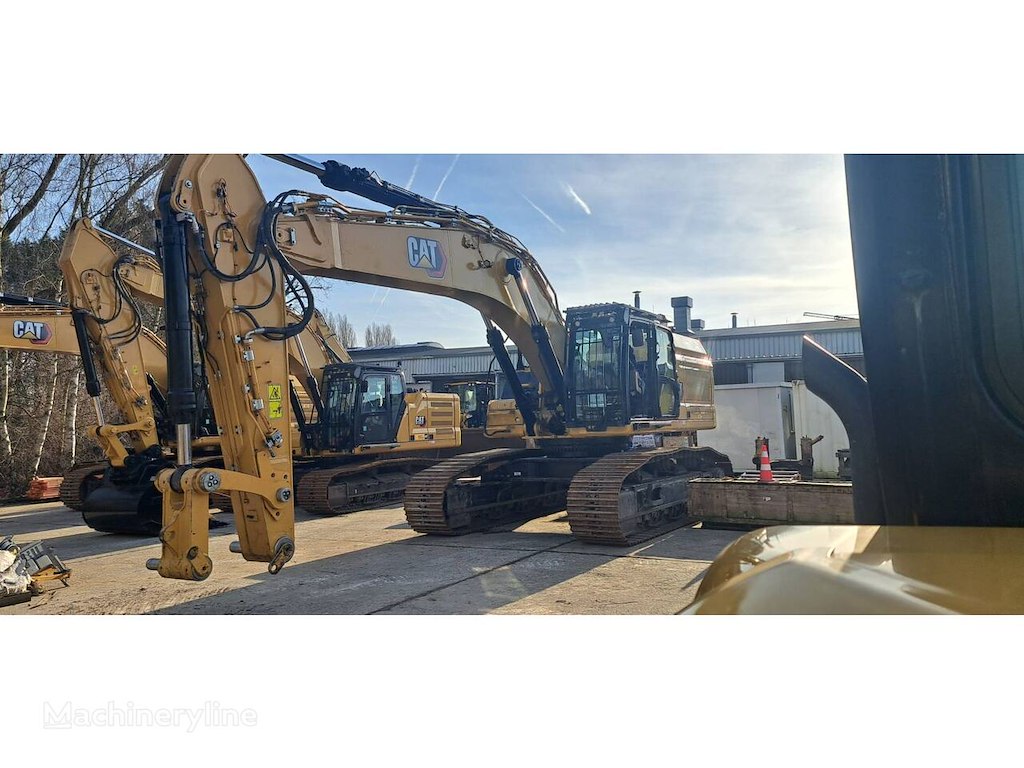

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Anti-theft System Auto Lube Auxiliary Hydraulics Pressure - High Pressure Boom - 1 Piece Boom Check Valve CE Plate Combined Hydraulics - One Way Grading System - 2D Lighting Mirrors Online Owner's Manual Payload Measurement System Radio Regulatory Status - EPA / ARB / EU / R120 / MLIT / Korea Stick - Medium Stick Check Valve Ultra Low Sulfur Diesel Fuel: SAFETY ITEMS: Cab Guards: Yes ROPS: Yes Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good GAUGES, OPERATOR STATION, CONSOLE: Back Up Alarm: No Current O&MM: Yes Current Parts Manual: Yes Current Safety Manual: No ROPS Certification Plate: Yes Air Conditioner: Good Dash Console: Good Door Latches: Good EMS Panel / Warnings: Good Floor Boards: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Knocking: No Oil Leaks: No Water in Oil: No COOLING SYSTEM: Compression in Radiator: No Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Block Heater: No Ether Aid: Yes Alternator: Good Batteries / Cables: Good Lighting: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Travel Motors: Good BOOM: Boom Length (Actual Length): 6.9 M Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Stick Length: 2.9 M Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good UNDERCARRIAGE: Idlers Front:Links:Track Roller 1:Track Roller 2:Track Roller 4:Track Roller 6:Track Roller 8:Track Roller 9: FINAL DRIVES: Housings: Good Poruka Poruka

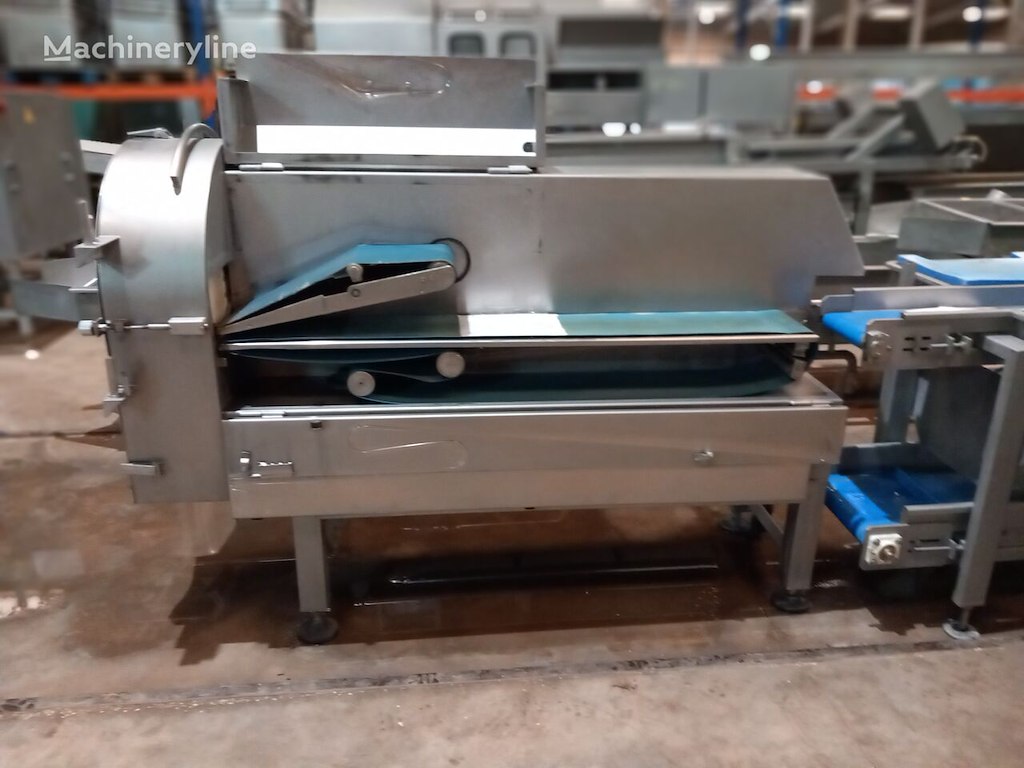

Conveyor belt speed: 0-27 m/min blade diameter: 790 mm Conveyor belt width: 250 mm Wattage: 3,5 KW Dimensions: 3100x1000x1500 mm Weight: 650kg Length of the Kronen GS10: 1610 mm Quantity in Stock: 3 Width: 670 mm Height: 1275 mm Length: 3 meters Feeding height: 777 mm Discharge/exit height: 470 mm Belt width: 125 mm Bottom bracket height: 130 mm Conveyor speed: 2.2-16.4 m/min Theoretical cutting thickness: 1-130mm full power: 1,8 kW Tension: 230 V N/PE Capacity: 2000 kg/hour Products: Leafy vegetables, various types of cabbage, kale, leeks, peppers, etc. Other specifications: Slices/Strips, Square Cutting for Lettuces, High Capacity Special Knife Sets for Cabbage Frequency: 50Hz Soup preparation line consisting of an EILLERT stainless steel preparation table, with feeder belt and residue/waste mat; vegetable cutting/preparation machine for soups from the EILLERT brand, type G4400, from 2001; lifting mat with stainless steel structure from the EILLERT brand with wheels; two stainless steel tanks from the EILLERT brand. G-4400 is a universal vegetable slicing machine, developed for larger capacities and use in vegetable processing companies, frozen food companies, vegetable dehydration companies, etc. The vegetable slicing machine is extremely suitable for cutting leafy vegetables (endive, various types of lettuce) as well as elongated vegetables such as Chinese cabbage, leeks and green beans. With the optional adjustable slicing disc, made with three crescent-shaped knives, cabbage and paprika can also be sliced. The machine is realized with PLC control. The knife and belt are checked frequently. Through a display, the cutting size is easy to adjust, as is the machine speed. The belt and knife speed are increased or decreased synchronously. Poruka Poruka

Burg hydro bin filler for filling storage bins with delicate fruit, such as apples and pears The hydro bin filler is a product designed by Burg for filling storage bins with floating and non-floating fruit, such as apples and pears. This bin filler is used in combination with a (pre) sorting line, after which the sorted fruit, coming from the exit of the grading machine, has to be stored in storage bins. The bins are filled with product in a fruit-friendly way. The bin is filled by means of a water stream that brings the fruit to the bin, while the bin is submerged in water. - 2 x conveyor belt - Disc conveyor for elevating, stainless steel frame - All Scales HPR-Ultra weighing conveyor belt with 4 loadcells - Set how many kg will be in a bin - Water buffer tank, for buffering the fruit before filling - Bin can rotate for non-floating fruits, such as pears - Roller conveyor belt for empty and full boxes - Stainless steel frame - Machines stays on the flat floor - By digging the filler bin into the ground, the elevating belt and weighing belt are no longer necessary. The first water hopper can then be placed directly at the grading machine. Making the total length of the machine 720 cm. More information or a quote? Do this quick and easily via the Duijndam Machines website! You can also give us a call. See all the available machines at our website. - Since 1977 supplier of reliable used agricultural and horticultural equipment - Machines are checked for delivery - Experienced team - We can help you with getting the machine to your company Duijndam Machines The specialist in used agriculture and horticulture machinery = More information = Year of manufacture: 2018 General condition: very good Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

pokazati kontakte Polymer Modification Plant Full Automatic TECHNICAL SPECIFICATIONS Grinding and homogenizing Polymer (SBS,APP,KRATON etc.) and bitumen. Feeding : Bitumen and polymer pre-mixture Flow rate : max. 15 t/hour Density : 1.1 g/cm3 Viscosity : max.20000 mPa s (cP) Heat: 190 °C Solid Matter : Machine Entrance :max. 3-6 mm Machine Exit :max. 0.2 mm MOTOR 130 kW Speed 3000 min-1 Voltage 400 V,50 Hz,3 phase Starting methode Y/Δ 2. VERTICAL MIXING TANK a) Frame - Will be manufactured as vertical rectangular profile. - Will be manufactured in dimentions as providing 11 m3 volumes. - Body will be produce 5 mm St37 quality plate. - Bitumen filling pipe will be 3’’ DN80 ,PN16,DIN2633 1 unit, discharge pipe will be 3’’ DN150,PN16,DIN2633 and 3’’ DN80,PN16,DIN 2633 2 units. - Control cover will be dimensions of 500x500 mm. b) Heating - It will be as providing from from out walls with diathermic hot oil heating. - Imperviousness test will not be performed under 6 bar. c) Insulation - 100 mm rapid wire-mesh rock wool will be comply with TSE ( Turkish Standards Institute ) standarts. - The exterior surface will be stainless steel plate and will be manufactured as to container dimentions. d) Mixing System - 2x 7,5 kW 60 d/min rpm mixing motor - Drive will be provided with sprockets - Imperviousness will be obtained at beddings. - Bearings will be SKF or FAG. - The Fixed wings at exteriror walls will be mounted so that dispersion will be increased and a homogeneous structure will be provided. e) Heat displays will be digital and analogue and two outlets will exits. f) Built-in connection paddle, ladders and platform will be presented. 3. BITUMEN PUMPS - Will be 2 ½ XLA type with oil heating. - Pump capacity will be as 25 t/h bitumen pumping - Will be 7,5 kW 400 r/min reducer motor coupled. 4. SBS (POLYMER MODIFIED GRANULE) FEEDING UNIT a) Feed Hopper - Will have 500 x 500 gap width - Will be produced of 4mm plate - In feding helix, it will be mounted with bolt30 m3/h capacity granulate feeding. - Frame will be in 5 mm Wall thickness from 220 mm diameter pipe. - Imperviousness will be provided in beddings. - In bearings SKF or FAG will be used. - Will 5,5 kW 80 rpm gear unit with coupling drive. 5. PIPE NETWORK AND EQUIPMENTS a) Pipes - Will be steel drawn pipes DIN 171175 (DN200,DN150,DN100,DN80,DN65,DN25) - Mill line will be manufactured as 3’’ inner pipe, 4’’ out jacket pipe. - Jacket pipes will be welded connection under TSE standarts. - Jumper pipes will be established from appropriate points of 1’’. b) Compensatories - DN 50,DN 80, PN 16 400°C c) 3 ways and 2 ways valves with heating - Complied to TSE standarts. - Pneumatic control type will be used. - Will provide the conditions of working under high pressure (16 bar) and heat (230 °C) d) Hot Oil Valves - KLINGER or THERMO branded hot oil valve with pistons will be used. - Will be DN 25 PN16, DN65 PN16, DN50 PN16 e) Filter - Will be with 3 mm wire interior reservoir and it will be cleanable often and easy. - Will be with 3’’ flange entrance and exit pipe. 6. ELECTRIC AND CONTROL SYSTEM - Air - Conditioned operator station (2000x2400 mm) - System will be PLC controlled. (SIEMENS) - Shalt and control panel will be present in the system. - The panel will be in type of compiled to IC standarts. - The mixing period and heat will be controlled automatically. - The PMB prepared at the system will be automatically serviced to stock tank. - All of the valves will be controlled at the operation panel by pneumatic actuators during all processed performed. - Heats and flow will be monitored digitally and manually. 7. CHASSIS - It will be manufactured as container. - Bottom chassis will be manufactured by NPI 220 profile. - All columns and tendons will be manufactured by 120 x 120 bin profile as bin. - Lifting crampon will be disposed to proper area. - There will be platform, barrier and ladder Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Polymer Modification Plant Full Automatic TECHNICAL SPECIFICATIONS Grinding and homogenizing Polymer (SBS,APP,KRATON etc.) and bitumen. Feeding : Bitumen and polymer pre-mixture Flow rate : max. 15 t/hour Density : 1.1 g/cm3 Viscosity : max.20000 mPa s (cP) Heat: 190 °C Solid Matter : Machine Entrance :max. 3-6 mm Machine Exit :max. 0.2 mm MOTOR 130 kW Speed 3000 min-1 Voltage 400 V,50 Hz,3 phase Starting methode Y/Δ 2. VERTICAL MIXING TANK a) Frame - Will be manufactured as vertical rectangular profile. - Will be manufactured in dimentions as providing 11 m3 volumes. - Body will be produce 5 mm St37 quality plate. - Bitumen filling pipe will be 3’’ DN80 ,PN16,DIN2633 1 unit, discharge pipe will be 3’’ DN150,PN16,DIN2633 and 3’’ DN80,PN16,DIN 2633 2 units. - Control cover will be dimensions of 500x500 mm. b) Heating - It will be as providing from from out walls with diathermic hot oil heating. - Imperviousness test will not be performed under 6 bar. c) Insulation - 100 mm rapid wire-mesh rock wool will be comply with TSE ( Turkish Standards Institute ) standarts. - The exterior surface will be stainless steel plate and will be manufactured as to container dimentions. d) Mixing System - 2x 7,5 kW 60 d/min rpm mixing motor - Drive will be provided with sprockets - Imperviousness will be obtained at beddings. - Bearings will be SKF or FAG. - The Fixed wings at exteriror walls will be mounted so that dispersion will be increased and a homogeneous structure will be provided. e) Heat displays will be digital and analogue and two outlets will exits. f) Built-in connection paddle, ladders and platform will be presented. 3. BITUMEN PUMPS - Will be 2 ½ XLA type with oil heating. - Pump capacity will be as 25 t/h bitumen pumping - Will be 7,5 kW 400 r/min reducer motor coupled. 4. SBS (POLYMER MODIFIED GRANULE) FEEDING UNIT a) Feed Hopper - Will have 500 x 500 gap width - Will be produced of 4mm plate - In feding helix, it will be mounted with bolt30 m3/h capacity granulate feeding. - Frame will be in 5 mm Wall thickness from 220 mm diameter pipe. - Imperviousness will be provided in beddings. - In bearings SKF or FAG will be used. - Will 5,5 kW 80 rpm gear unit with coupling drive. 5. PIPE NETWORK AND EQUIPMENTS a) Pipes - Will be steel drawn pipes DIN 171175 (DN200,DN150,DN100,DN80,DN65,DN25) - Mill line will be manufactured as 3’’ inner pipe, 4’’ out jacket pipe. - Jacket pipes will be welded connection under TSE standarts. - Jumper pipes will be established from appropriate points of 1’’. b) Compensatories - DN 50,DN 80, PN 16 400°C c) 3 ways and 2 ways valves with heating - Complied to TSE standarts. - Pneumatic control type will be used. - Will provide the conditions of working under high pressure (16 bar) and heat (230 °C) d) Hot Oil Valves - KLINGER or THERMO branded hot oil valve with pistons will be used. - Will be DN 25 PN16, DN65 PN16, DN50 PN16 e) Filter - Will be with 3 mm wire interior reservoir and it will be cleanable often and easy. - Will be with 3’’ flange entrance and exit pipe. 6. ELECTRIC AND CONTROL SYSTEM - Air - Conditioned operator station (2000x2400 mm) - System will be PLC controlled. (SIEMENS) - Shalt and control panel will be present in the system. - The panel will be in type of compiled to IC standarts. - The mixing period and heat will be controlled automatically. - The PMB prepared at the system will be automatically serviced to stock tank. - All of the valves will be controlled at the operation panel by pneumatic actuators during all processed performed. - Heats and flow will be monitored digitally and manually. 7. CHASSIS - It will be manufactured as container. - Bottom chassis will be manufactured by NPI 220 profile. - All columns and tendons will be manufactured by 120 x 120 bin profile as bin. - Lifting crampon will be disposed to proper area. - There will be platform, barrier and ladder Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Boom - 1 Piece Car Body - Standard CE Plate Coupler - Quick Coupler Type - Mechanical Hand and Foot Control Lighting Online Owner's Manual Rubber TrackGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Bumper: Good Car Body: Good Catwalk: Good Counterweight: Good Crankcase Guard / Battery Box: Good Decals: Good Draw Bar: Good Eng. Enclose Hood / Stack: Good Engine Doors: Good Fenders: Good Fiberglass: Good Fuel Tank: Good Grab Irons: Good Hood: Good Main Frame Welds: Good Paint: Good Plastic: Good Pre-Cleaner Bowl: Good Radiator Grill & Shroud: Good Sheet Metal: Good Steps / Ladder: Good SAFETY ITEMS: Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Fire Extinguisher: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good OPERATOR STATION: Dash Console: Good Door Latches: Good EMS Panel / Warnings: Good Floor Boards: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Knocking: No Oil Leaks: No Water in Oil: No Belts / Pulleys: Good Fuel Injection System: Good Governor: Good Turbocharger / Blower: Good COOLING SYSTEM: Compression in Radiator: No Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Alternator: Good Batteries / Cables: Good Beacon: Good Lighting: Good Pre-Heater: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Travel Motors: Good BOOM: Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good BUCKET: Quick Coupler: Yes Bucket Bottom: Good Bucket Linkage: Good Bucket Mounts: Good Bucket Sides: Good Cutting Edges: Good Teeth / Adapters: Good UNDERCARRIAGE: Track Frame - Left: Good Track Frame - Right: Good FINAL DRIVES: Housings: Good Planetaries / Diff: Good Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Boom - 1 Piece Car Body - Standard CE Plate Engine Enclosures Hand and Foot Control Lighting Online Owner's Manual Radio - Bluetooth Rubber TrackGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Bumper: Good Car Body: Good Catwalk: Good Counterweight: Good Crankcase Guard / Battery Box: Good Decals: Good Draw Bar: Good Eng. Enclose Hood / Stack: Good Engine Doors: Good Fenders: Good Fiberglass: Good Fuel Tank: Good Grab Irons: Good Hood: Good Main Frame Welds: Good Paint: Good Plastic: Good Pre-Cleaner Bowl: Good Radiator Grill & Shroud: Good Sheet Metal: Good Steps / Ladder: Good SAFETY ITEMS: Cab Guards: No ROPS: No Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Fire Extinguisher: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good OPERATOR STATION: Air Conditioner: Good Dash Console: Good Door Latches: Good EMS Panel / Warnings: Good Floor Boards: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Knocking: No Oil Leaks: No Water in Oil: No Belts / Pulleys: Good Fuel Injection System: Good Governor: Good Turbocharger / Blower: Good COOLING SYSTEM: Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Alternator: Good Batteries / Cables: Good Beacon: Good Lighting: Good Pre-Heater: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Thumb Cylinder: Good Travel Motors: Good BOOM: Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good BUCKET: Quick Coupler: No Bucket Bottom: Good Bucket Linkage: Good Bucket Mounts: Good Bucket Sides: Good Cutting Edges: Good Teeth / Adapters: Good UNDERCARRIAGE: Track Frame - Left: Good Track Frame - Right: Good FINAL DRIVES: Housings: Good Planetaries / Diff: Good Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Boom - 1 Piece Car Body - Standard CE Plate Emissions Level - EPA - EPA TIER 4f Emissions Level - EU - EU STAGE V Engine Enclosures Hand and Foot Control Lighting Online Owner's Manual Radio Rubber TrackGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Bumper: Good Car Body: Good Catwalk: Good Counterweight: Good Crankcase Guard / Battery Box: Good Decals: Good Draw Bar: Good Eng. Enclose Hood / Stack: Good Engine Doors: Good Fenders: Good Fiberglass: Good Fuel Tank: Good Grab Irons: Good Hood: Good Main Frame Welds: Good Paint: Good Plastic: Good Radiator Grill & Shroud: Good Sheet Metal: Good Steps / Ladder: Good SAFETY ITEMS: Cab Guards: Yes Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Fire Extinguisher: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good OPERATOR STATION: Back Up Alarm: Yes Air Conditioner: Good Dash Console: Good Door Latches: Good EMS Panel / Warnings: Good Floor Boards: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Knocking: No Oil Leaks: No Water in Oil: No Belts / Pulleys: Good Fuel Injection System: Good Governor: Good Turbocharger / Blower: Good COOLING SYSTEM: Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Alternator: Good Batteries / Cables: Good Beacon: Good Lighting: Good Pre-Heater: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Travel Motors: Good BOOM: Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good BUCKET: Quick Coupler: No Bucket Bottom: Good Bucket Sides: Good Cutting Edges: Good Teeth / Adapters: Good UNDERCARRIAGE: Track Frame - Left: Good Track Frame - Right: Good FINAL DRIVES: Housings: Good Planetaries / Diff: Good Poruka Poruka

Preis: Contact us for price Marke: Karlville Tornado shrink tunnel Refurbished -(better conveyor belt testing of electronics new motor for turntable drive etc.) However the tunnel was hardly used by us and was only used for testing purposes. The tunnel itself is from December 2008. Type: 2500 The manufacturer of the tunnel is a professional in the field of shrink sleeves. It is the company Karlville with a branch in France The actual tunnel is about 2.40 metres wide and has a depth of about 80 cm. In addition there is a conveyor belt for entry and exit and a so-called round table to buffer the finished product It can handle everything from the packaging of dierent-shaped containers to liquids dried goods empty containers etc Tornado - Electric Tunnel The newest addition to our product line the tornado tunnel is an electric shrinking system ideal for use on steam sensitive applications. With the capability to create a superior shrink appearance similar to steam tunnels on almost any container shape this tunnel generates a compact solution to applications where high quality shrinking is required and the use of steam is not acceptable The Tornado provides the best solution for Shrinking for Difficult Shaped Containers Shrinking for Water Sensitive Products Shrinking for Heat Sensitive Containers like PET Eliminating After-Shrink Wrinkles Saving Energy - High Efficiency Design Saving Space - No Need for Extra Leister Guns and Special Rotation Systems Minimizing Mechanical Maintenance - Simple Machine Structure Eliminating the need for Steam Boiler and Infrastructure. This is Ideal for Blow Molders Contract Packers and Thermo formers 4x Film Types: PVC OPS PETG & PLA 4x Common Means to Shrink Sleeves – Steam – Hot Air (Commonly with Rotation) – Leister Guns – Radiant Heat Container Type Shape Size Product type Pre / Post Fill Factory Environment and Conditions Dictate Shrink Method Short run items variety of container shapes / sizes cause longer change over's and set ups Increased Demand for Down gauging Labels and Containers Demand for Environmentally Responsible Label Materials (Wal-Mart Scorecard) Typical Find more here pokazati kontakte Poruka Poruka

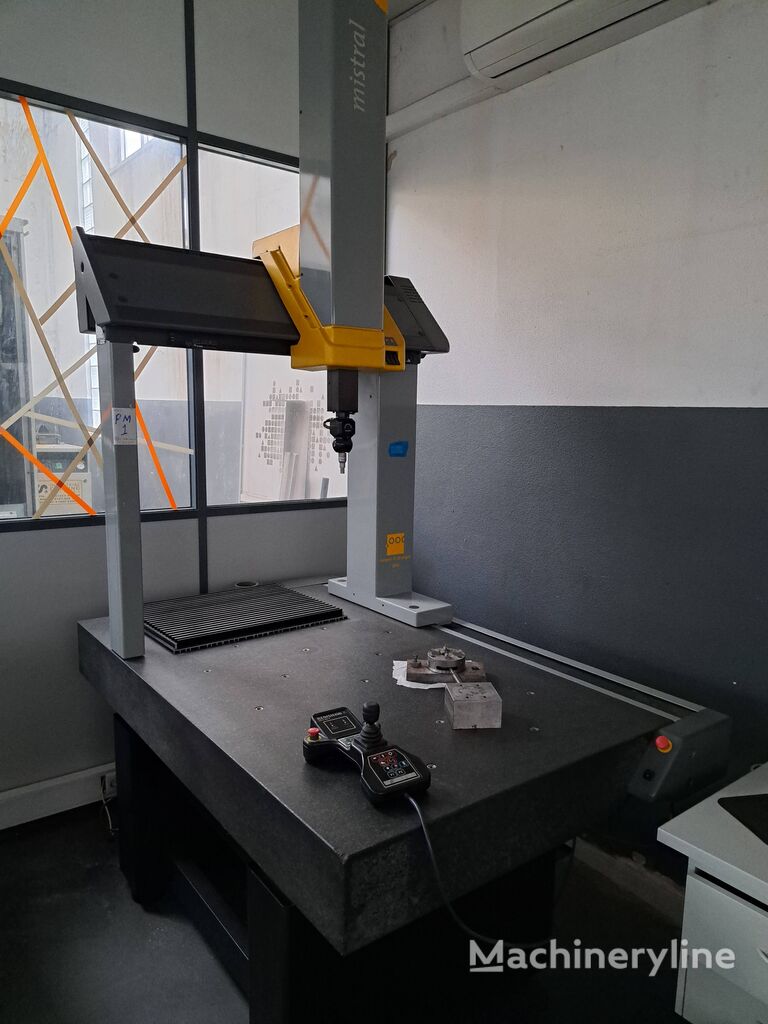

Effective stroke L0 (mm): 120 (4.5") Motorized X-Y Axis: Optional CNC control: Optional Focus range (in): 2" Focus range (mm): 50 output signal step: 20μm Mass Load: 180 kg X axis measurement: 210mm Measurement Interval: 0 - 972mm Maximum response speed: 50m/min scale reference point: 50mm steps Protection Level: IP53 System Type: Upper Workbench load height: 560 mm Cable length: 3 mt Precision Rotary Lathe: Optional Precision Fixed Lathe: Optional Accuracy (20°C): (3+3L0/1000)μm Work Internship (in.): 21.25" x 5" Working phase (mm): 540 x 130 control: CNCFanuc 18i-M CNC Control Angular measurement resolution: 1 minute profile lighting: Pattern Cabinet Support 32": Optional Cabinet Support 23": Optional 4-5th axis ready: Yes Rotative desk: two-axis Nikken Table dimensions: 30" x 70" Load capacity: 2000 lbs. main engine: 15 hp spindle speeds: 60-8000 rpm conical tool: CAT-40 tool stations: 21 Repeatability: (2σ) Flat Air Cushion: yes, full/semi-floating Compensation method: counter balance No. of memorized programs: 50 programs (max.) stack autonomy: approx. 5 hours measuring force: 1N Imperial-Metric: Metric/Inch Z axis measurement: 420mm cone iso: 40/50 Tension: 230 V machine dimensions: 1.50x0.55x1.70m Screen Diameter (in.): 16 " Screen diameter (mm): 400 compatible counter: KA counter / KLD200 counter Operating Temperature: 0 to 45°C Block Number: 1 Accumulated height (µm): 10 skate course: 600 mm Perpendicularity: 5 µm (after compensation) Surface Lighting: Pattern Control system/software: QC100/200/5200, M2, M3 optical edge detection: optional iris diaphragm: Optional 700/900: 0.02 µm Weight: 1.530 kg Forward Speed: 519 mm/s (3-axis) Range: 500x700x400mm Accuracy: E0, MPE from- (0.7+0.25L/100) µm digital resolution: 500- 0.05 µm Exit sign: Double sine wave with 90° shift A highly accurate CNC Coordinate Measuring Machine that allows you to achieve exact results at lightning speed. The STRATO-APEX Series has the following advantages: - High accuracy measurement and high travel speed - High performance sweep. - Rulers with ultra high accuracy on each axis. - An anti-vibration system reduces the impact of nearby vibration sources. Poruka Poruka

Description Modular labeling machine 10 heads Modular labeling machine Cold glue • 4 stations: Front/back, seal L, neck ring self-adhesive • 3 stations: Front/back, neck ring Bottles : round/square Label stations nr.: N. 3 self-adhesive stations N. 3 Cold glue stations Central diameter Ø: Ø 960 Plates nr.: 10 Length of the labels min/max: 10/150 Height of the label min/max: 15/200 Container diameter/height min/max: Ø 30/80 mm – Altezza min/max 100/400 mm Plate transmission Motorized plate Optical centering Yes Special inlet stars No. 3 multi-format in/out stars D 50->120 mm Industria 4.0 yes predisposed other request Double screw input in phase Max speed request: 6.500 bph Modular labeling machine: basic machine composition 1. System built according to CE regulations 2. Machine operation via PLC (Schneider) 3. Touch-screen control panel for labeler functions installed on a mobile and rotating support 4. Automatic variation of production speed with inverters and detection sensors installed on the conveyor belts 5. Light column indicating the operating status of the labeler 6. Electrical cabinet fixed internally to the machine body. 7. Accident prevention protections consisting of: ➢ On the screw front, with two swing doors ➢ On the labeling station front, single-part circulars a vertical lift 8. Height-adjustable upper head for different containers with gearmotor, panel adjustment, and automatic stop limit switch 9. Plate rotation via electronic cams 10. Shaped plates 11. The transmission between the plate and the motor occurs via a maintenance-free gear reducer 12. Quick plate change 13. The body of plates removable from the lower carousel (complete with all their transmission) 14. Double inlet auger with stop-in phase 15. N. 3 40M adhesive labeling stations, including: · Stepper motor · Machine stops after two labels are missing on the reel · Memory for 200 different labels · Automatic missing label recovery function · 4-axis adjustment system, without tools · Reel exhaustion sensor · Standard photocell for labels FOR TRANSPARENT 16. L-shaped sealing pliers with 4 DIVISIONS 17. N.3 Cold glue labeling station, type: 2-2-150, including: · Motorization with servomotor · Automatic glue film adjustment · Automatic washing of the drum tweezers for label removal. · Glue pump · Forced oil lubrication · No greasing points · Radial and tangential adjustment with machine in production · MANUAL GROUP HEIGHT ADJUSTMENT WITHOUT HEIGHT CHANGE 18. Teleassistance 19. N.1 Equipment for CYLINDRICAL container format consisting of: · Nr. 1 container introduction screws with UNIVERSAL container shape FOR BOTTLE DIAMETERS FROM 50 TO 120 MM · Nr. 1 UNIVERSAL entry/exit star WITH HANDS · Nr. 1 central container guide · No. 10 clay pigeons 20. Optical centering LOGO OR WELDING following with FOLLOWER 2 system 21. N. 5 Smoothing station for labels 22. N.1 Cold glue body label or back label equipment · N. 1 label warehouse · N. 1 set of label-picking pallets; · N. 1 label picking pliers drum; · N.1 label smoothing station. 23. N.1 Label equipment for cold glue collar · N. 1 label warehouse · N. 1 set of label-picking pallets; · N. 1 label picking pliers drum; · N.1 label smoothing station. 24. N.1 Cold glue “L” seal equipment · N. 1 label warehouse · N. 1 set of label-picking pallets; · N. 1 label picking pliers drum; · N.1 set of pads and hands for the seal pliers. Modular labeling machine standard parameters ✓ Supporting and upper structure in hot-dip galvanized steel ✓ Top and side cover in AISI 304 ➢ Container transfer The spacer screw, the input/output stars, and the central guide are made of wear-resistant synthetic material. The lateral and belt sliding guides are made of plastic ➢ Carousel The container locking heads have a height tolerance of up to 15 mm ➢ PLATE HANDLING: ELECTRONIC CAM ➢ Self-adhesive labeling station The self-adhesive station was created in modules independent of each other and fixed on a modular aluminum profile – Paper unwinder – Label peeling blade – Drive roller – Support paper rewinder – Electrical panel with quick connections. Each individual group can be quickly and easily replaced. The station is fixed to a solid mechanical structure, equipped with 4 adjustment axes, complete with format position indicators. The technique of the Modular labeler: The label drive motor is perfectly synchronized with the speed of the labeler detected and controlled by a single high-resolution encoder. The label dispensing speed is variable. By stopping the machine during labeling with the label dispensed halfway, it is possible to restart without having defects in the application of the label on the container. The paper drive roller is specifically treated to prevent glue residues from self-adhesive labels from adhering (the option is present starting from 60 MT/min modules). Ergonomic: all adjustments take place in the upper part of the self-adhesive assembly. All adjustments occur without tools and are indicated in red. The degree of protection is IP65. Electronics Digital control electronics. Terminal for programming and storing the various types of labels (200 max). No mechanical/manual adjustment of the speed ratio and format adjustment. The machine stops after two labels are missing on the reel. Automatic missing label recovery function. ➢ Smoothing The smoothing, customized for each individual format, includes brushes and/or rollers that can be removed as a whole for replacement without the use of tools. For certain applications, an additional smoothing device can be mounted on the belt. ➢ Transmission and main control The transmission to all moving parts is given by alternating gears in C40 and Zellamid steel. The central motorization is provided by a gear motor driven by an “Inverter” electronic frequency converter. ➢ Speed regulation and automatic control The production speed of the machine is totally automatic and is variable based on the incoming flow and outgoing disposal of the containers. Furthermore, a stop device, installed at the machine entrance, guarantees a minimum accumulation of containers at the machine entrance and an automatic safety stop in the event of an accumulation of containers at the machine exit. Everything is managed by a PLC. ➢ Pneumatic system Service group incorporated into the modular labeling machine with regulation valve and water separating filter ready for an existing connection. ➢ Electrical installation CE-compliant system, ready for connection to the network. Voltage according to customer specifications. Control voltage 24 V DC ➢ Maintenance Manual, individual, and grouped greasing points. Low-maintenance materials are used on the panel, such as sealed ball bearings and self-lubricating sliding materials. Periodic check of the oil level in the spacer screw. The Manufacturer reserves the right to make technical changes based on what is described. techniqueThe label drive motor is perfectly synchronized with the speed of the labeler detected and controlled by a single high-resolution encoder. The label dispensing speed is variable. By stopping the machine during labeling with the label dispensed halfway, it is possible to restart without having defects in the application of the label on the container. The paper drive roller is specifically treated to prevent glue residues from self-adhesive labels from adhering (the option is present starting from 60 MT/min modules). Ergonomic: all adjustments take place in the upper part of the self-adhesive assembly. All adjustments occur without tools and are indicated in red. The degree of protection is IP65. Electronics Digital control electronics. Terminal for programming and storing the various types of labels (200 max). No mechanical/manual adjustment of the speed ratio and format adjustment. The machine stops after two labels are missing on the reel. Automatic missing label recovery function. ➢ Smoothing The smoothing, customized for each individual format, includes brushes and/or rollers that can be removed as a whole for replacement without the use of tools. For certain applications, an additional smoothing device can be mounted on the belt. ➢ Transmission and main control, Optical centering, and electronic cams The transmission to all moving parts is given by alternating gears in C40 and Zellamid steel. The central motorization is provided by a gear motor driven by an “Inverter” electronic frequency converter. ➢ Speed regulation and automatic control The production speed of the modular labeling machine is totally automatic and is variable based on the incoming flow and outgoing disposal of the containers. Furthermore, a stop device, installed at the machine entrance, guarantees a minimum accumulation of containers at the machine entrance and an automatic safety stop in the event of an accumulation of containers at the machine exit. Everything is managed by a PLC. ➢ Pneumatic system Service group incorporated into the machine with regulation valve and water separating filter ready for an existing connection. ➢ Electrical installation CE compliant sy Speed: 6500 BPH Containers: Glass No. of plates: 10 Plate movement: Electronic brushless motors Number of stations: 7 Rotation direction: Counterclockwise Labeling method: Adhesive, Cold glue Label adjustment: Auto Head adjustment: Electric Add. label smoothing at machine exit: Yes Safety features: Yes Manuals: Yes Poruka Poruka

Description Used adhesive labeling machine PE labelers overhauled up to 6000 BPH Complete transformation from a mechanical machine to an electronic machine Used rotary labeler overhauled up to 6000 complete replacement of the head with new plates, motors, boards, and double jacks for optical centering replacement of groups with 3 new adhesive groups PE labeler or PackLab type. complete overhaul of the glue group for the l-shaped seal for the PE labelers review of seal stretching pliers new electrical panel new complete and CE standard protections for the PE labelers installation of the touchscreen and plc control panel new certifications for Used labeler rotary machine overhauled up to 6000 a bottle passage format for the Used adhesive labeling machine overhauled up to 6000 composed of: auger entry/exit star counter star 11. one seal format per glue group for adhesive rotary labeling up to 6000 complete with: 1 warehouse 3 blades 1 hook drum Delivery time equipment of the Used adhesive labeling machine overhauled: This PE labeler can be serviced and delivered in approximately 90 working days from the order and payment of the first deposit. It is important to approve all technical drawings and label measurements for the PE labelers. This allows orders for replacement materials for the PE labelers to be prepared in an efficient time. In this particular historical period, we encounter very long delivery dates for electrical materials. Is for this reason that it is very important to plan the entire project in the correct direction to avoid wasting time for the PE labelers overloaded. For the installation of the PE labelers we only use our own direct workers, to give safety to our customers. We follow the entire process from start to finish and to the commissioning of the new or used machinery. Speed: 6000 BPH Containers: Glass No. of plates: 8 Plate movement: Electronic cam stepper/stepper motor Number of stations: 3 Rotation direction: Clockwise Labeling method: Adhesive Label adjustment: Auto Head adjustment: Electric Safety features: Yes Manuals: Yes marca: P.E. Labellers stato: In storage Poruka Poruka

Range: 500x700x400mm Measurement uncertainty: 1.7 + 3L/1000, 1.9 [µm] spindle speeds: 60-8000 rpm conical tool: CAT-40 tool stations: 21 X axis measurement: 210mm Measurement Interval: 0 - 972mm Measuring area: X 700, Y 1000, Z 700 [mm] Accuracy: E0, MPE from- (0.7+0.25L/100) µm Forward Speed: 519 mm/s (3-axis) 3D travel speed: 500mm/s cone iso: 40/50 Tension: 230 V machine dimensions: 1.50x0.55x1.70m Screen Diameter (in.): 16 " Screen diameter (mm): 400 Motorized X-Y Axis: Optional CNC control: Optional Focus range (in): 2" Focus range (mm): 50 Work Internship (in.): 21.25" x 5" Working phase (mm): 540 x 130 control: CNCFanuc 18i-M CNC Control Angular measurement resolution: 1 minute profile lighting: Pattern Surface Lighting: Pattern Control system/software: QC100/200/5200, M2, M3 optical edge detection: optional iris diaphragm: Optional Precision Rotary Lathe: Optional Precision Fixed Lathe: Optional Cabinet Support 32": Optional Cabinet Support 23": Optional 4-5th axis ready: Yes Rotative desk: two-axis Nikken Table dimensions: 30" x 70" Load capacity: 2000 lbs. main engine: 15 hp 3D Acceleration: 2500 mm/s² Mass Load: 180 kg load height: 560 mm digital resolution: 500- 0.05 µm 700/900: 0.02 µm Weight: 1.530 kg Effective stroke L0 (mm): 120 (4.5") System Type: Upper Workbench Cable length: 3 mt Accuracy (20°C): (3+3L0/1000)μm Exit sign: Double sine wave with 90° shift Maximum response speed: 50m/min output signal step: 20μm scale reference point: 50mm steps Protection Level: IP53 compatible counter: KA counter / KLD200 counter Operating Temperature: 0 to 45°C Block Number: 1 Accumulated height (µm): 10 skate course: 600 mm Perpendicularity: 5 µm (after compensation) Repeatability: (2σ) Flat Air Cushion: yes, full/semi-floating Compensation method: counter balance No. of memorized programs: 50 programs (max.) stack autonomy: approx. 5 hours measuring force: 1N Imperial-Metric: Metric/Inch Z axis measurement: 420mm 3D Coordinate Measuring Machine in high-accuracy gantry design that allows you to achieve exact results at lightning speed. Note: Technical characteristics may not correspond exactly to the advertised product. We advise Customers to visit and find out the specifications of the equipment. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Anti-theft System Auto Lube Auxiliary Hydraulics Pressure - High Pressure Boom - 2 Piece Boom Check Valve Car Body - Standard CE Plate Combined Hydraulics - Two Way Coupler - Quick Coupler Type - Hydraulic Emissions Level - EPA - EPA TIER 4f Emissions Level - EU - IV Emissions Level - Japan - STEP 4 FINAL Lighting Mirrors Online Owner's Manual Pilot Control Radio - AM FM Radio Stick - Long Stick Check Valve Ultra Low Sulfur Diesel Fuel Undercarriage, LongGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Bumper: Good Car Body: Good Counterweight: Fair Crankcase Guard / Battery Box: Good Fuel Tank: Good Main Frame Welds: Good Radiator Grill & Shroud: Good SAFETY ITEMS: Cab Guards: No ROPS: Yes Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Horn: Good Secondary Exit: Good Swing Brake: Good GAUGES, OPERATOR STATION, CONSOLE: Back Up Alarm: No Current O&MM: Yes Current Safety Manual: Yes ROPS Certification Plate: Yes Air Conditioner: Good Dash Console: Good Door Latches: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Oil Leaks: No Water in Oil: No Belts / Pulleys: Good Fuel Injection System: Good Governor: Good Turbocharger / Blower: Good COOLING SYSTEM: Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Alternator: Good Batteries / Cables: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Hose Lines: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Travel Motors: Good BOOM: Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Stick Length: 2.1 M Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good BUCKET: Quick Coupler: Yes Notes - BUCKET: 1 curage inclinable 1850 mm et 1 terrassement 900 mm OK 50% Quick Coupler (Make/Model): miller hyd UNDERCARRIAGE: Notes - UNDERCARRIAGE: sur patins caoutchouc OK 30% Notes - UNDERCARRIAGE 1: TDR OK 50% Track Shoes: 500 mm 3AR Track Frame - Left: Good Track Frame - Right: Good COMMENTS, MISC. REPAIRS, GENERAL REMARKS: comment 1: largeur de transport 2.5 M comment 2: FR-24 Poruka Poruka

Description Used Labeling Machine KHS Anker up to 1850 bph This labeling machine offers an efficient option for bottling production lines. This machine, which KHS manufactured in 2001, delivers high performance with a labeling speed of up to 1850 bottles per hour (bph). Moreover, the machine operates and remains in perfect working condition. Technical Features of the Used Labeling Machine KHS Anker Firstly, the used labeling machine KHS Anker up to 1850 bph includes two plates and 15 labeling stations, with a counterclockwise rotation direction. Consequently, this design ensures a continuous and smooth workflow, maintaining high production standards. Additionally, the hot glue labeling method provides quick adhesion and a clean finish of the labels. Automatic Adjustments The KHS Anker up to 1850 bph features automatic glue level adjustment in the rollers. Thus, this system maintains consistent labeling quality, reducing downtime for manual adjustments. Furthermore, the electronically adjustable labeling head ensures superior precision during the process. Safety and Manuals The used labeling machine KHS Anker up to 1850 bph includes all necessary safety features, ensuring a safe working environment. Specifically, detailed manuals cover every aspect of operation and maintenance, making it easier for technicians to intervene when needed. Additional Features Additionally, the machine provides an additional label smoothing system at the machine exit, ensuring perfect application without air bubbles or wrinkles. The machine measures 3 meters in length, 2.5 meters in height, and 1.8 meters in width, thus requiring adequate installation space in the workspace. Electrical Specifications In terms of electrical specifications, the machine includes a voltage of 400V and a frequency of 50Hz. Therefore, this compatibility with standard industrial electrical systems facilitates integration into existing production lines. Conclusion of the Used Labeling Machine KHS Anker In conclusion, this machine offers a highly efficient and technologically advanced solution for labeling operations. Its numerous automatic functions, safety features, and available manuals make it an excellent choice for improving productivity and quality in the bottling process. Speed: 1850 BPH Containers: Glass No. of plates: 2 Plate movement: N/A Number of stations: 15 Rotation direction: Counterclockwise Labeling method: Hot glue Label adjustment: Auto Head adjustment: Electric Safety features: Yes Manuals: Yes stato: In production Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Anti-theft System Auto Lube Auxiliary Hydraulics Pressure - High Pressure Boom - 1 Piece Boom Check Valve CE Plate Combined Hydraulics - One Way Coupler - Quick Coupler Type - Hydraulic Grading System - 2D Lighting Mirrors Online Owner's Manual Payload Measurement System Radio Regulatory Status - EPA / ARB / EU / R120 / MLIT / Korea Stick - Short Stick Check Valve Ultra Low Sulfur Diesel FuelGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No Car Body: Good Counterweight: Good Crankcase Guard / Battery Box: Good Decals: Good Eng. Enclose Hood / Stack: Good Engine Doors: Good Fiberglass: Good Fuel Tank: Good Grab Irons: Good Hood: Good Main Frame Welds: Good Paint: Good Plastic: Good Pre-Cleaner Bowl: Good Radiator Grill & Shroud: Good Sheet Metal: Good Steps / Ladder: Good SAFETY ITEMS: Cab Guards: Yes ROPS: No Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Secondary Exit: Good Swing Brake: Good GAUGES, OPERATOR STATION, CONSOLE: ROPS Certification Plate: Yes Air Conditioner: Good Dash Console: Good Door Latches: Good Floor Boards: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Knocking: No Oil Leaks: No Water in Oil: No COOLING SYSTEM: Compression in Radiator: No Coolers: Good Fan: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Ether Aid: Yes Alternator: Good Batteries / Cables: Good Lighting: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: Good Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Travel Motors: Good BOOM: Boom Length (Actual Length): 6,9M Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Stick Length: 2,9 M Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good UNDERCARRIAGE: Idlers Front:Links:Track Roller 1:Track Roller 2:Track Roller 4:Track Roller 6:Track Roller 8:Track Roller 9: FINAL DRIVES: Housings: Good COMMENTS, MISC. REPAIRS, GENERAL REMARKS: comment 1: machine in good condition Poruka Poruka

| Loading table | FRAMAX | | | | Labeling Machine | FRAMAX | | | | Filling Monoblock | FRAMAX | | | capper Arol | Accumulation Table | FRAMAX | | | Description Used complete bottling line FRAMAX year 2016 Configuration and Versatility The complete 2016 FRAMAX bottling line is currently configured for 330ml long neck bottles. As the line has been used to produce beer. A notable aspect is the inclusion of interchangeable parts for (taller) Vichy bottles, demonstrating the versatility of the line. The availability of replacement components for 500ml and 660ml bottles further amplifies this flexibility. This system is supplied with a set of interchangeable parts for larger bottles, presumably 660ml, but these have never been used. Dimensions and Capping Capacity of the Used complete bottling line FRAMAX year 2016 A point of technical interest is the beer line’s ability to handle different sizes of caps, in particular the 26mm and 29mm formats. Currently, the cap configuration is set to 26mm, with replacement components available for larger caps. This flexibility in capping is crucial to adapt to different packaging requirements. Technical Specifications of the Bottles Regarding the minimum and maximum dimensions of the bottles that can be used on the line, it is important to consider the specifications relating to the 330/500 and 660ml bottles. Although FRAMAX can provide details on the maximum dimensions supported by the interchangeable components, for existing parts, the width of the bottles does not present many restrictions thanks to the adjustable inlet and outlet guide rails. The interchangeable parts for the boot wheels and perspex guards at the entry and exit points of the filling station are quite extensive. Regarding height there are no obvious impediments. Total Production Time of the Used complete bottling line FRAMAX year 2016 A relevant figure is the total production time of the line, which amounts to 2084 hours and 7 minutes. This indicates moderate use of the equipment, suggesting that most components are in excellent condition. Furthermore, the equipment was described as “new and never used”, which suggests a high level of maintenance and conservation.In conclusion, the 2016 FRAMAX complete bottling line represents a technologically advanced and versatile solution, suitable for a wide range of bottling needs. Its configurability for different types and sizes of bottles and caps, combined with its state of preservation and limited production time, makes it an attractive option for operators in the bottling sector who require efficiency and adaptability. Containers: Glass Formats: 0.33 L, 0.50 L, 0.66 L Product: Beer Fill type: Isobaric Poruka Poruka

AM FM RADIO ULTRA LOW SULFUR DIESEL FUEL AUTO TRACTION CONTROL BEACON PRODUCT LINK RETARDER BED, STANDARD CE PLATE EROPS ENGINE BRAKE LIGHTING SIDE BOARDS AIR CONDITIONER AIR SUSPENSION SEAT REAR VIEW CAMERA BLUETOOTH RADIO: SAFETY ITEMS: Horn: Good Secondary Exit: Good : ENGINE: Blow By: No Compression in Radiator: No Fluid Levels OK?: Yes Knocking: No Oil Leaks: Yes Water in Oil: No Air Cleaners: Good Engine Brake: Good Engine Supports: Good Fuel Injection System: Good Operating Condition - ENGINE: Good Turbocharger / Blower: Good COOLING SYSTEM: Leaks - COOLING SYSTEM: No Belts / Pulleys: Good Coolers: Good Fan: Good Hoses: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Ether Aid: Yes Alternator: Good Batteries / Cables: Good Starter: Good Wiring: Good TRANSMISSION: Leaks - TRANSMISSION: No Transmission - Noisy: No Case: Good Controls: Good Cooler: Good Lines / Fittings - TRANSMISSION: Good Overall Operating Condition - TRANSMISSION: Good Pump - TRANSMISSION: Good Retarder: Good Seals: Good Temp / Pressure Gauges: Good Torque Converter: Good Transmission - Forward Shifts: Good Transmission - Reverse Shifts: Good STEERING: Lines / Fittings - STEERING: Good Steering Cylinder: Good Steering Linkage: Good SUSPENSION: Suspension Cylinders: Good BRAKE: Leaks - BRAKE: No Accumulators - BRAKE: Good Brake Drums / Rotors: Good Control Valve: Good Hydraulic Cooler: Good Lines: Good Pedal: Good Pump - BRAKE: Good Type (Wet, Dry): Good HYDRAULICS: Leaks - HYDRAULICS: No Lift Cylinders: Good TRUCK BODY: Bed Liner: Good Bottom: Good Hinge Pins & Brackets: Good Operating Condition - TRUCK BODY: Good Ribs and Stringers: Good Spill Guard: Good FINAL DRIVES: Center Axle: Good Center Final Drives: Good Front Axle - FINAL DRIVES: Good Front Final Drives: Good Rear Axle: Good Rear Final Drives: Good Universal Joints: Good Wheel Lugs & Rims: Good TIRES: Tire Size - TIRES: 29.5R25 Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "No" / Tread cuts chunks - "No" Left Center: Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "Yes" / Tread cuts chunks - "Yes" Left Front: Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "No" / Tread cuts chunks - "No" Left Rear: Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "Yes" / Tread cuts chunks - "Yes" Right Center: Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "No" / Tread cuts chunks - "No" Right Front: Make serial number - "Michelin " / Percentage life left - "Michelin %" / Recapped - "No" / Side cuts section - "Yes" / Tread cuts chunks - "Yes" Right Rear: Poruka Poruka

-

Mašine i alati chevron_right Ručni alat i rezervni delovi

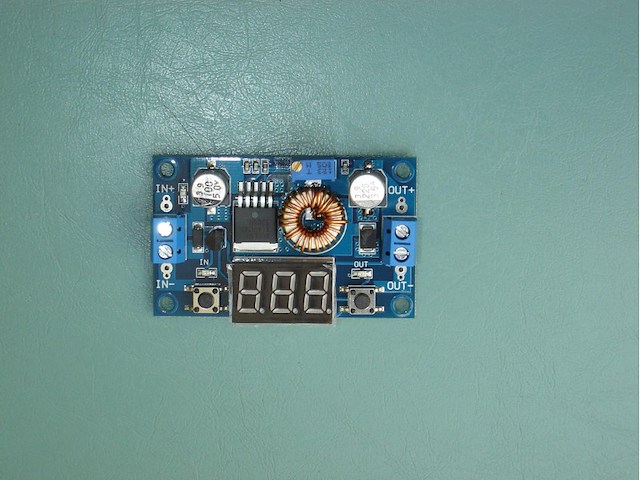

P06 Performance parameters: 1.Input voltage range:4-38VDC(Note:input voltage not exceeding 38V) 2.Output voltage range:1.25-36VDC adjustable 3.Output current:5A max 4.Output power: 75W 5.voltmeter range: 4 to 40V, error ±0.1V 6.Operating frequency: 180KHz 7.High efficiency up to 96% 8.Built in thermal shutdown function 9.Built in current limit function 10.Built in output short protection function 11.Input reverse polarity protection: None (if required, high current diode in series with the input). 12.L x W x H =6*3.7*1.8CM Features: 1. LED power indicator. 2. Button to switch measurement of the input or output voltage, and LED indicates the current measurement of the input or output voltage; The nixie tube can be turned off by another button. Mentioned states are able to be memorized, is not lost even if the power is disconnected. (On-board marked `IN` LED is turned on, the nixie tube display input voltage value, `OUT` LED bright display is the output voltage value). 3. Special launch, the voltmeter calibration function, will never exist voltmeter inaccurate! Voltmeter calibration method: (1) Output voltage calibration steps Step 1, adjust the right button so that `OUT` LED lighted, the voltmeter shows the value of output voltage; Press the right button for more than 2 seconds, release, voltmeter and `OUT` LED flashes in synchronization so that you enter the output voltage calibration mode. Step 2, press the right button (normal speed), the voltage value is adding up a unit; Press the left button, minus a unit; Due to a unit is less than 0.1V, the minimum voltage display to 0.1V, so you need to continuously press 1-5 times to see the voltmeter change 0.1V, how many times voltmeter change 0.1V by pressing the key, depending on the current display voltage, the higher the voltage, the fewer the number of press. Step 3, press the right button for more than 2 seconds, release, to exit the output voltage calibration mode. All parameters set to automatically power down to save. (2) Input voltage calibration steps Step 1, adjust the right button so that `IN` LED lighted, the voltmeter shows the value of input voltage; press the right button for more than 2 seconds, release, voltmeter and `IN` LED flashes in synchronization so that you enter the input voltage calibration mode. Steps 2 and 3, consistent with the output voltage calibration method.

Preis: Contact us for price Food conveying and processing equipment List of equipment 1. Dewatering shaker (fabricated in Q4 2020) 2. Weight conveyor belt (fabricated in Q4 2020) 3. Dejuicing shaker (fabricated in Q4 2020) 4. Diagonal shaker (fabricated in Q4 2020) 5. Dryer feeding shaker (fabricated in Q4 2020) 6. Incline belt elevator (fabricated in 2021) 1. DEWATERING SHAKER Dimensions Features Fully built in stainless steel Tray fully built-in stainless-steel plate composed by 1 Dewatering screens of 1.000x600mm Juice collecting level and canalisation outside the machine Vibration by means of fibber springs working at high frequency Reaction mass in 5 mm stainless steel plate Isolation by means of rubber silent blocks Chassis in stainless steel structural profile for the required working height Powered by-mass motor-vibrators (OLI trademark) Supported over columns 2. WEIGHT CONVEYOR BELT Dimensions Features Fully built in Stainless Steel AISI-304 Belt Intralox thermoplastic and modular material Traction by thermoplastic sprockets Retaining sides Floating scraper for cleaning of the belt Driven by pendular SEW motor gearbox with bidirectional working mode Motor gearbox cover Side protections placed in transmission zones to avoid risk of entrapment Stainless Steel bearings Weight cells and DAT 400 weight system 3. DEJUICING SHAKER Dimensions Features Fully built in stainless steel Tray fully built-in stainless-steel plate composed by 6 dewatering screens of 1.000x600mm Juice collecting level and canalisation outside the machine Vibration by means of fibber springs working at high frequency Reaction mass in 5 mm stainless steel plate Isolation by means of rubber silent blocks Chassis in stainless steel structural profile for the required working height Powered by-mass motor-vibrators (OLI trademark) Supported over columns Diagonal exit 4. DIAGONAL SHAKER Dimensions Input width: 800 mm Features Fully built in stainless Steel High frequency technology Tray fully built in 3mm stainless steel plate Reaction mass in 5mm stainless steel plate Fiber springs Shaker composed by Reception area Discharging area by means of a diagonal cut angle to feed the following machine in the complete with Powered by moto vibrators Supporting structure for the required working height Isolation by rubber silent-blocks 5. DRYER FEEDING SHAKE Dimensions Input width: 2.500 mm Features Fully built in stainless Steel High frequency technology Tray fully built in 3mm stainless steel plate Reaction mass in 5mm stainless steel plate Fiber springs Powered by moto vibrators Supporting structure for the required working height Isolation by rubber silent-blocks 6. INCLINED BELT ELEVATOR Find more here pokazati kontakte Contact us at pokazati kontakte Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Air Conditioner Anti-theft System Auto Lube Auxiliary Hydraulics Pressure - High Pressure Boom - 1 Piece Boom Check Valve CE Plate Combined Hydraulics - One Way Coupler Type - Hydraulic EPA Label Hand and Foot Control Lighting Mirrors Online Owner's Manual Product Link Radio - AM FM Radio Stick - Medium Stick Check Valve Ultra Low Sulfur Diesel FuelGENERAL APPEARANCE: Cleaning Required: No Extra Fuel Tanks: No S.O.S. Taken: No Bumper: Good Catwalk: (Poor) Counterweight: Good Crankcase Guard / Battery Box: Good Decals: Good Eng. Enclose Hood / Stack: Good Engine Doors: Good Fuel Tank: Good Grab Irons: Good Hood: Good Main Frame Welds: Good Paint: Good Plastic: Good Pre-Cleaner Bowl: Good Radiator Grill & Shroud: Good Sheet Metal: (Fair) Steps / Ladder: Good SAFETY ITEMS: Cab Guards: Yes ROPS: Yes Safety Decals In Place: Yes Safety Decals Legible: Yes Brake Hold: Good Horn: Good Rig Saver: Good Secondary Exit: Good Swing Brake: Good GAUGES, OPERATOR STATION, CONSOLE: Back Up Alarm: No Current O&MM: No Current Parts Manual: No ROPS Certification Plate: Yes Air Conditioner: Good Dash Console: Good Door Latches: (Fair) Floor Boards: Good Gauges: Good Glass/Mirrors: (Fair) Heater: Good Interior Lights: Good Meter: Good Product Link: Good Seat Belt: Good Seat Cushion / Arm Rest: Good Switches: (Fair) Windshield Wipers: Good ENGINE: Blow By: No Compression in Radiator: No Emissions Decal: Yes Fluid Levels OK?: Yes Knocking: No Oil Leaks: No Water in Oil: No Air Cleaners: Good Belts / Pulleys: Good Engine Supports: Good Exhaust / Muffler: Good Fuel Injection System: Good Governor: Good Operating Condition - ENGINE: Good Turbocharger / Blower: Good COOLING SYSTEM: Leaks: No Coolers: Good Fan: Good Fan Drive: Good Hoses: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Ether Aid: Yes Alternator: Good Batteries / Cables: Good Lighting: Good Starter: Good Wiring: Good HYDRAULICS: Boom Cylinder: Good Bucket Cylinder: Good Control Linkage: Good Hose Lines: Good Hydraulic Swivel: Good Operating Condition - HYDRAULICS: Good Pump Drive: Good Pumps & Valves: (Fair) Stick Cylinder: Good Swing Gear: Good Swing Motors: Good Tank: Good Thumb Cylinder: Good Travel Motors: Good BOOM: Boom Length (Actual Length): 6.9 M Boom Condition: Good Boom Pins: Good Pins & Bushings - BOOM: Good STICK: Stick Length: 3.4 M Pins & Bushings - STICK: Good Stick Conditions: Good Stick Pins: Good UNDERCARRIAGE: Notes - UNDERCARRIAGE 1: er onrbreken bouten van de trackshoes, en er zijn een aantal trackshoes geplooid. Idlers Front:Links:Track Roller 1:Track Roller 2:Track Roller 4:Track Roller 6:Track Roller 8:Track Roller 9: FINAL DRIVES: Housings: Good COMMENTS, MISC. REPAIRS, GENERAL REMARKS: comment 1: er onrbreken bouten van de trackshoes, en er zijn een aantal trackshoes geplooid. comment 2: nazicht van lock valve van stick cilinder comment 3: switch van claxon stuk , start/stop knop gele beschermrand stuk, beschermplaat rond hendel afgeplakt, Poruka Poruka

AIR CONDITIONER AIR SUSPENSION SEAT AM FM RADIO ANTI-THEFT SYSTEM AUTO LUBE AUTO TRACTION CONTROL BEACON BED, STANDARD CE PLATE ENGINE BRAKE FAST FUEL LIGHTING Online Owner's Manual PRODUCT LINK REAR VIEW CAMERA RETARDER SUPP STEER TAILGATE ULTRA LOW SULFUR DIESEL FUELGENERAL APPEARANCE: Cleaning Required: No S.O.S. Taken: No Bumper: Good Cab or Canopy: Good Decals: Good Fenders: Good Fuel Tank: Good Grab Irons: Good Paint: Good Pre-Cleaner Bowl: Good Sheet Metal: Good Steps / Ladder: Good SAFETY ITEMS: ROPS: Yes ROPS Certification Plate: Yes Horn: Good Secondary Exit: Good GAUGES, OPERATOR STATION, CONSOLE: Current O&MM: No Current Parts Manual: No Current Safety Manual: No Air Conditioner: Good Dash Console: Good Gauges: Good Glass/Mirrors: Good Heater: Good Interior Lights: Good Seat Cushion / Arm Rest: Good Second Seat: Good Switches: Good Windshield Wipers: Good ENGINE: Blow By: No Compression in Radiator: No Fluid Levels OK?: Yes Knocking: No Oil Leaks: No Water in Oil: No Air Cleaners: Good Engine Brake: Good Engine Supports: Good Fuel Injection System: Good Operating Condition - ENGINE: Good Turbocharger / Blower: Good COOLING SYSTEM: Leaks - COOLING SYSTEM: No Belts / Pulleys: Good Coolers: Good Fan: Good Hoses: Good Radiator: Good Water Pump: Good ELECTRICAL, STARTING AND CHARGING SYSTEM: Block Heater: No Ether Aid: Yes Alternator: Good Batteries / Cables: Good Starter: Good Wiring: Good TRANSMISSION: Leaks - TRANSMISSION: No Transmission - Noisy: No Case: Good Controls: Good Cooler: Good Lines / Fittings - TRANSMISSION: Good Overall Operating Condition - TRANSMISSION: Good Pump - TRANSMISSION: Good Retarder: Good Seals: Good Temp / Pressure Gauges: Good Torque Converter: Good Transmission - Forward Shifts: Good Transmission - Reverse Shifts: Good STEERING: Hand Metering Unit: Good Lines / Fittings - STEERING: Good Steering Cylinder: Good Steering Linkage: Good SUSPENSION: Suspension Cylinders: Good BRAKE: Leaks - BRAKE: No Accumulators - BRAKE: Good Brake Drums / Rotors: Good Control Valve: Good Hydraulic Cooler: Good Lines: Good Pedal: Good Pump - BRAKE: Good Type (Wet, Dry): Good HYDRAULICS: Leaks - HYDRAULICS: No Lift Cylinders: Good TRUCK BODY: Bed Liner: Good Bottom: Good Hinge Pins & Brackets: Good Operating Condition - TRUCK BODY: Good Ribs and Stringers: Good Spill Guard: Good Tailgate: Good FINAL DRIVES: Center Axle: Good Center Final Drives: Good Front Axle - FINAL DRIVES: Good Front Final Drives: Good Rear Axle: Good Rear Final Drives: Good Universal Joints: Good Wheel Lugs & Rims: Good TIRES: Average Life Remaining - TIRES: 90 procent Tire Size - TIRES: 750/65 R25 Make serial number - "michelin defend" / Percentage life left - "michelin defend%" Left Center: Make serial number - "Michelin defend" / Percentage life left - "Michelin defend%" Left Front: Make serial number - "michelin defend" / Percentage life left - "michelin defend%" Left Rear: Make serial number - "michelin defend" / Percentage life left - "michelin defend%" Right Center: Make serial number - "michelin defend" / Percentage life left - "michelin defend%" Right Front: Make serial number - "michelin defnd" / Percentage life left - "michelin defnd%" Right Rear: Poruka Poruka