Pratite promene cene putem maila

- Da bi dobijali obaveštenja o promeni cene potrebno je da kliknete Prati oglas dugme koje se nalazi na dnu svakog oglasa i unesete Vašu mail adresu.

226-250 od 724 rezultata

Broj oglasa

Prikaz

Prati pretragu "power plate"

Vi se opustite, Gogi će Vas obavestiti kad pronađe nove oglase za tražene ključne reči.

Gogi će vas obavestiti kada pronađe nove oglase.

Režim promene aktivan!

Upravo ste u režimu promene sačuvane pretrage za frazu .

Možete da promenite frazu ili filtere i sačuvate trenutno stanje

-

Mašine i alati chevron_right Građevinske mašine

PE600*900 Jaw Crusher Stone Crusher Line Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Ormig 16 tmE Pick & Carry Crane 100% Electric LIKE NEW CONDITION Lifting capacity at 0,8 m from front plate: DIN 16 t – SAE 17,6 t Drive: Front Boom height: 11,5 m Working outreach: 7 m Boom angle: – 5° + 57° Hydraulic JIB Tyres: 10.00-R20 Capacity of each tyre: max. static 8000 kg Speed: 12,19 Km/h Power Source: 96 Volt 900 Ah Electric Motor: 36 kW Hydraulic and Service Motor: 26 kW Poruka Poruka

bore capacity in steel (diameter) 50 mm arm length 1100 mm workpiece height max. ca. 1000 mm bore capacity in cast iron 60 mm spindle taper MK 5 spindle turning speed range 28 - 2500 U/min feeds 0,05 - 2 mm/U quill stroke 300 mm distance basic plate - spindle nose 630 - 1380 mm crossrail adjustment vertical 750 mm total power requirement 6 kW weight of the machine ca. 4 t dimensions of machine L x W x H 2,74 x 1,14 x 2,59 mm - with thread cutting attachment - Accessories: box table 550 x 550 x 550 mm, vice, coolant The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

This ARBURG ALLROUNDER CENTEX 520 C 2000-675 Injection moulding machine was manufactured in 1998 in Germany. It has a clamping force of 2000 kN, an opening stroke of 650 mm and is equipped with an injection unit with 55mm screw diameter. The plate dimensions are 715x715 mm and distance between columns is 900 mm. It is still under power and can be inspected on-site anytime. application type: Injection Moulding Location: Italy machine type: Injection Moulding Machines availability: Immediately GINDUMAC ID: IT-INJ-ARB-1998-00001 Screw diameter: 55 mm Injection pressure: 1720 bar Heating capacity: 14.9 kW Clamping force: 2000 kN Opening stroke: 650 mm Distance between bars: 900 mm Size of mold platens: 715 x 715 mm Main electronic connection: 400 V 3 ~ 50 HZ Pump drive power: 1 x 30 kW Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

New Kinglink KPF1416 Hydraulic Impact Crusher (Minyu MIC133152) Model: KPF1416 Motor power:185-220kw Working Diameter of Rotor:1330mm Effective Width of Rotor:1524mm Feed Opening:1540x1065mm Discharge opening range:19-76mm Capacity:192-422tph Advantages of KPF series hydraulic impact crusher: -Hydraulic clearing device to clear out oversized rock -Hydraulic hood opening for quick wear plate replacement -Extra large feed opening -Positive rotor lock for safty during blow bar changeing Poruka Poruka

turning diameter over bed 650 mm turning diameter over slide rest 440 mm turning length 7000 mm centre height 330 mm centre distance 7000 mm spindle bore 61 mmø spindle turning speed range 8 - 800 U/min total power requirement kW weight of the machine ca. 5,9 t dimensions of machine L x W x H 8,75 x 1,35 x 1,48 m Accessories: face plate 450 mmø, 4-pos. tool holder, running center, coolant pump The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

Boring power 23.0 / 28.0 mm Boring depth max. 140 mm Center of spindle to wall or column 300 mm Column diameter 125 mm Size of table plate 415 x 385 mm Speed 100 - 2000 U/min. spindle taper MT 2 MK voltage 380 V Motor output 0.9 / 1.4 KW weight of the machine ca. 225 kg Dimensions (L/W/H) 900 x 600 x 1960 mm ** maintained condition (!!) Furnishing: - V-belt operated column drilling machine - adjustable drilling depth stop - Pole-changing drive motor - manual spindle feed via cross handle - Work table with 2x T-slots - Keyless drill chuck including taper mandrel - Table height adjustment via hand crank - machined base plate with 3x T-slots - manual V-belt tension (front handwheel) - Connection cable including 16A plug * Machine link: pokazati kontakte The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

Surface plate diameter 1000 mm Swing diameter 1650 mm Max. turn height 1100 mm Travels: X axis -1010 / +1010 mm Y axis 600 mm Z axis 1250 mm C axis 360 ° Tool magazine number of tools 40 Spindle nose: KM63 Tool section 40 mm Milling cutter speeds: stepless from 10 rpm up to 3000 rpm Torque max. 1000 Nm Power 31 kW Table load max. 3000 kg Table speeds: stepless from 5 rpm up to 800 rpm Engine power 60 kW Feeds 0.1 - 3000 mm/min Rapid traverse: 10 m/min Voltage 50 Hz 3x 400 Volt Total power required 196 kW Machine's weight about 35000 kg Various accessories: Coolant system Set of toolholders Chip conveyor Pallets chanching device: Pallets: number 2 Poruka Poruka

cutting dimensions max. 600 x 1000 mm plate thickness max. 3 mm cutting angle 1,5 ° side stop electrical adjustable 0 - 1010 mm rear stop electrical adjustable 0 - 610 mm no. of strokes 60 Hub/min total power requirement 14 kW weight of the machine ca. 8,7 t dimensions of machine L x W x H 2,5 x 2,18 x 2,3 m Accessories: sheet metal stacking device on rails The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

sheet width 3000 mm plate thickness 6 mm distance between columns 3100 mm cutting angle 1°15´ no. of strokes 16 Hub/min down holder 16 Stück back stop - adjustable 750 mm total power requirement 11 kW weight of the machine ca. 5,7 t dimensions of machine L x W x H 4,1 x 2,08 x 1,78 m Accessories: electr. back stop with DRO ELGO electric, angle front stop The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

length 6500 mm width 3000 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 4 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 6500 mm width 3000 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 4 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 6500 mm width 3000 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 4 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 6500 mm width 3000 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 4 total power requirement kW weight of the machine ca. t The Palttenfeld consists of 4 plates, size per plate 3250x1500 mm, number of T-grooves per column 7, price 1000 â¬/m² The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

length 9750 mm width 4500 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 9 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 9750 mm width 4500 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 9 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 9750 mm width 4500 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 9 total power requirement kW weight of the machine ca. t dimensions of the machine ca. m length 9750 mm width 4500 mm Thickness 250 mm T-slot - width 32/48 mm T-slot - distance 180 mm number 9 total power requirement kW weight of the machine ca. t The Palttenfeld consists of 9 plates, size per plate 3250x1500 mm, number of T-grooves per column 7, price 1200 â¬/m² The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

Used very clean well maintained LVD 2.5metre x 6mm Plate Shear / guillotine for sale LVD HST-C 25/6 for sale Age: Year 2008 Description LVD HST-C 25/6 Technical information Cutting length 2500 mm Max sheet thickness 6,350 mm Strokes/min 13-50 /min Adjustable cutting device 0,05-0,800 mm Adjustable cutting edge 0.5-2,5° Electric motor (power) 7,5 kW Complete with: Simatic OP7 control and powered back gauge Poruka Poruka

-

Mašine i alati chevron_right Ručni alat i rezervni delovi

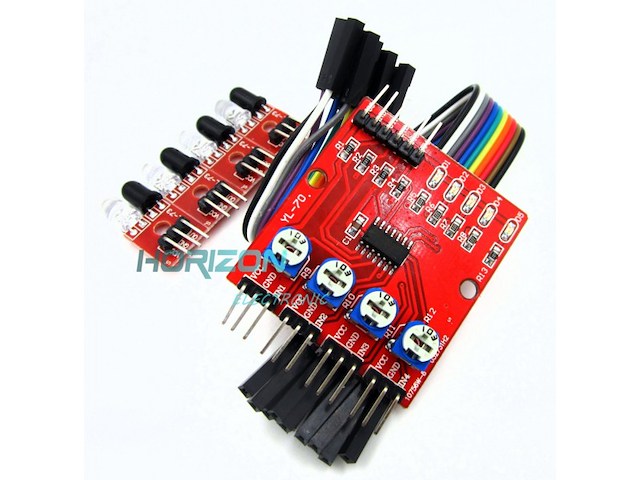

P09 Item Description: 1.Operating voltage: DC 3.3V-5V 2.Operating Current: try to choose more than 1A power supply 3.Operating Temperature: -10 ° C - +50 ° C 4.mounting aperture: M3 screw 5.detection distance: 1mm to 60 cm adjustable closer the performance is more stable, the white reflection farthest. 6.Size: the control board 4.4mm × 4.0mm × 12mm (L × W × H) Small plate forward 25mm x 12mm x 12mm (L × W × H) The output interface: 6-wire interface (1234 for the 4-way signal output terminal, + positive power, - the negative power supply is ground) Output signal: TTL level (directly connected microcontroller I / 0, sensitive to infrared light reflected back by the sensor, the red light is on, the output low; absence of infrared light, the light does not shine, the output high level.) Applications: A smart car or robot hunt (including black and white lines), walking along the path of the black line, also known as tracing. Smart car to avoid the cliff, anti-drop. Smart car for obstacle avoidance

-

Mašine i alati chevron_right Građevinske mašine

brand: KINGLINK Kinglink WBW-140 Apron Feeder Apron feeder a fixed feeder is the accessory equipment for conveying machinery. Apron feeder is widely applied for short-distance conveying especially for heavy big and abrasive materials in harsh conditions and in the industries of metallurgy mining cement and chemical industry etc Model: WBW-140 Chain Plate Width: 1400 mm Head & Tail Shaft Distance: 16000 mm Speed: 0.006-0.06 m/s Max. Feed Size: 700 mm Capacity: 20-200 t/h Electric Power: 22 kw Please whatsapp (+) me for more details! Poruka Poruka

Injection machine SANDRETTO HES 3500 (with MASTER MATTIC RB 500CN robot). 1.2 TECHNICAL DATA TYPE MEGA H ES MODEL KN 35000 EUROMAP CLASSIFICATION 54250 Control Panel SEF 2000 Thread diameter mm 200 L/D Ratio L/D 20 Theoretical injection volume cm3 36110-18000 Injection ratio cm3/s 3147 Maximum injection pressure Bar 1670 Plasticizing Capacity (HDPE) g/s 280 Plasticizing Speed RPM 0-110 Simultaneous Plasticizing Speed RPM 0-55 Maximum torque Nm 43000 Heating zones + nozzle n 6 + 1 Unit injection stroke mm 1600 Total heating power kW 174 Closing force kN 35000 Mold height min/max mm 1000÷2200 Opening stroke mm 2300 Plate dimensions (Horizontal x Vertical) mm 3360x3060 Passage between columns (Horizontal x Vertical) mm 2230x1930 Column diameter mm 470 Extraction force kN 550 Extraction stroke mm 600 No load cycle (Euromap) s 3.6 Oil tank capacity l 8000 Hydraulic system pressure bar 195 Electric motor power kW 528 (4x132) Total installed power kW 721 Machine dimensions (L x H x W) mm 19135 4440 5550 Machine Weight (closing – injection) ton 276 - 70 Fixed maximum weight 35tns PMM Maximum mobile weight 44,400tns PMM Total mold maximum 66,600tns PMM Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Stone Jaw crusher For Granite Stone,Industrial Equipment,Granite Crusher Machinery Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Special Design Widely Used Mining Crushing Rock Machine Granite Jaw Crusher Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Hard stone jaw crushers produced with good mechanism of the movement Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Crusher Primary 2021 Jaw Crusher As The Primary Crusher For Stone Crushing Plant Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Jaw Crusher PE/PEX Series Jaw Crusher China Products Manufacturers Crusher Machine Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

High Quality Jaw Crusher Heavy Industrial Duty Jaw Crusher Equipment Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

China Manufacturer Cobble Coal Clay Gravel Crushing Machine Lime Stone Jaw Crusher Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

philippines full line widely using industrial hard quarry stone jaw crushers Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka

-

Mašine i alati chevron_right Građevinske mašine

Reliable primary crushing PE 400X600 jaw crusher Mining Machinery crusher Streamlined structure, Convenient maintenance As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. 1. High ratio of crushing 2. Even final size 3. Simple structure 4. Reliable working condition 5. Easy maintenance, 6. Low operating cost Working Principle: The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet. We have got the certificate of European Union CE certification, ISO international quality system certification, and SZUTEST certification. Henan Liming Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipment was founded in 1987. It is a modern joint-stock corporation with research, manufacturing and sales together. Liming Heavy Industry is China top mining equipment manufacturer. Poruka Poruka