Pratite promene cene putem maila

- Da bi dobijali obaveštenja o promeni cene potrebno je da kliknete Prati oglas dugme koje se nalazi na dnu svakog oglasa i unesete Vašu mail adresu.

1-22 od 22 rezultata

Broj oglasa

Prikaz

1-22 od 22

1-22 od 22 rezultata

Prikaz

Prati pretragu "Gas gas ec"

Vi se opustite, Gogi će Vas obavestiti kad pronađe nove oglase za tražene ključne reči.

Gogi će vas obavestiti kada pronađe nove oglase.

Režim promene aktivan!

Upravo ste u režimu promene sačuvane pretrage za frazu .

Možete da promenite frazu ili filtere i sačuvate trenutno stanje

Engine Brand: MTU Conditie: CORE Engine Cooling Type: Exchanger (on engine) Engine Color: Grey Flywheel Housing SAE: SAE 00 Flywheel SAE: Unknown Engine Condition: Core Turbo Type: Dry Exhaust System: Dry ECU Present?: YES Starter Voltage: 24 Volt Rated Power: 880 Kw Rated Speed: 1500 Rpm Injection Type: ECU (Electronic Control Unit) pokazati kontakte = More information = Type: Engine Type number: 8V 4000 L63 Serial number: 000011860 Poruka Poruka

rack oven SVEBA-DAHLEN I-Series V - 42 eco+/ gas heated/for one rack trolley rack wagon sheet size up to 60 x 1000 mm inside and outside stainless steel/insulated bottom double viewing window/neon lighting rotating platform patented IBS system SD touch panel AES-automatic exhaust frequency converter patented steam system "Cascad" CE version two-stage gas burner "Weishaupt steam hood with external fan Eco+ (min. 35% less energy costs) Effect: 3 KW It is built for a Stikken with sheet dimensions of 1.00m * 0.60m The burner is from Weishaupt so it is a gas-fired furnace The performance data can be seen on the nameplate A steam exhaust hood with suction is also included Find more here pokazati kontakte Poruka Poruka

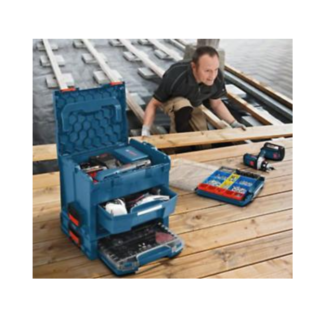

Odgovara za GBH 36 V-EC Compact. Kompletni uložak odgovara za L-BOXX 102 Idealna iskorišćenost prostora sa uloškom precizno skrojenim za alat i pribor te prilagodljiva primena pretinaca za pribor prilagođenih odgovarajućem alatu. Vrsta materijala: PS Težina: 0,3 kg Spoljne dimenzije (širina x dužina x visina): 402 x 50 x 315 mm

Preis: Contact us for price Marke: SVEBA-DAHLEN 2020 SVEBA-DAHLEN V - 42 eco+ Rack oven Rack oven Sveba-Dahlen V - 42 eco+ / gas-heated / for one rack trolley tray size up to rack trolley 60 x 1000 mm Stainless steel interior and exterior. Double viewing window and neon lighting. With rotating platform and patented IBS system. With SD touch panel . With AES automatic extraction With frequency converter. Patented ‘Cascad’ vapour system CE version. Two-stage gas burner ‘Weishaupt’ Insulated floor Vapour bonnet with external fan. Eco + version (At least 35% less energy costs) V-series Packed with unique features for the best baking results The V-series is reliable powerful and built to be easy and safe to use. They come in three basic sizes with up to four racks in the oven cavity and can be supplied with many different options to suit customer needs The V-series rack ovens are designed to meet the highest standards of operational safety. All materials and components are of high quality and sourced from the market's leading suppliers The ovens are tested and approved in accordance with market requirements. In addition each oven is tested for proper function before it leaves the factory Find more here pokazati kontakte Contact us at pokazati kontakte Poruka Poruka

-

Mašine i alati chevron_right Ručni alat i rezervni delovi

Adapter sa USB na RS232 za direktno vezivanje na mikrokontrolere ili slicna digitalna kola. Kolo koje se koristi je CH340G. Adapter sa USB na RS232 za direktno vezivanje na mikrokontrolere ili slicna digitalna kola. Kolo koje se koristi je CH340G. Features: Chip: CH340G Switchable output TTL level 3.3V/5V (with jumper) 3.3V and 5V output voltage to supply the programmed controller With power light PWR, TXD and RXD indicator light Used to upgrade various device Used for different diagnostics Can be used for Gas LPG ECU interface adjustments Specifications: Color: Golden Module size: Approx. 4 x 2.2cm / 1.57 x 0.86 inch

i/A310/A311 Li /A312 Li /A314 Li/A316 Li /A316/R308/R310/R313 Li /R317 Li/A312/A900B Li/A900C Li /A900C ZW /A900 Li/A900 ZW/A902 Li/A902 INDUSTRIAL/A904 Li/A904C Li/A910 comp/A912 compact/A912 Li/A914 Compact/A914 Li/A914B Li/A914C li/A916 /A918/A918 Compact/A920/A922 Li/A922 Rail/A924 Rail/A924 li/A924B Li/A924C Li/A928/A932 Li/A934 Li/A934B Li/A934C Li/A944 Li/A944B Li/A944C Li/A954 Li/A954B Li/A954C Li/LH22 C/LH22 M/LH24 M/LH26 EC/LH26 M/LH30 C/LH30 M/LH35 M/LH35 MT/LH40 C/LH40 M/LH50 M/LH50 MHR/LH50 MT/LH60 C/LH60 M/LH60 MHR/LH60 MT/LH80 C/LH80 M/LH80 MHR/R312/R900 Li/R900B Li/R900C Li /R914 compact/R934 IND/R984C/A900 B/R902 Li/R902 KHD ENGINE/R902 LIEBHERR ENGINE/R904C/R904/R906 ADVANCED//R912 Li/R914B/R914C/R914/R916 ADVANCED/R916 CLASSIC/R916 LC/R920/R922 Li/R924 B/R924 COMPACT/R924 C/R924 LC/R924 SLC/R926/R932 Li/R932 ENGINE LIEBHERR/R932 Li T/R934B/R934C/R934/R936/R942 LI/R944/R944B/R944C Li/R944C TU//R946/R954/R954B/R954C/R964B/R964C/R964 /R966/R970/R974/R974 Li/R974B/R974C Poruka Poruka

PRODATO Proizvod je rasprodat. Aktuelne proizvode iz ove kategorije možete pogledati klikom na dugme ispod: Vidi proizvode Opis i namena proizvoda Agregat za struju 2.2 KW EU22i Honda Naš najnoviji generator, EU22i, je 10% moćniji od svog prethodnika, dok je isto tako lagan i tih kao i ranije. EU22i poseduje pretvarač sa mikroračunarom koji garantuje električnu energiju komercijalnog kvaliteta - što ga čini idealnim za upotrebu sa frekventno osetljivom električnom opremom, kao što su laptop i kućni računari. EU22i poseduje ekološki gas koji podešava brzinu motora i radi samo sa punim kapacitetom kada je to potrebno. Ovo povećava ekonomičnost potrošnje goriva i smanjuje buku. Takođe poseduje paralelnu kompatibilnost. Za dodatnu snagu možete povezati dva generatora generatora Honda u paralelnim operacijama pomoću jednostavnog kabla za povezivanje. Karakteristike proizvoda Motor GKS120R Zapremina 121 cm3 Sistem za paljenje Transistor Oil Alert da Zaustavljanje sistema primarnog kola za paljenje Preporučeno gorivo bezolovno Upotreba goriva (približno) 1,14 (litara / sat) Kapacitet rezervoara goriva (litri) 3.6 Funkcija Fuel Off (Isključeno gorivo) Da - dozvoljava vam da uređaj radi u praznom hodu kako biste iskoristili gorivo kako biste pomogli u skladištenju i eliminisali zastarelo gorivo u gorivnim vodovima Neprekidno radno vreme 8.1 sati * Operativni nivo buke (na 7m) 48dB (A) * Dimenzije (DkŠkV) 511 x 290 x 425 (mm) Težina (kg) 21kg Maksimalni izlaz AC 2200 VA Nazivni AC izlaz 1800 VA DC izlaz (generator / punjač) 8.3A Punjenje baterije Da Tip generatora Mulitpole tip rotacije (invertor) Nazivni napon 240 (V) Nazivna frekvencija 50 (Hz) Merač goriva br Prekidač AC Da DC prekidač Da Auto gas Eco-throttle

PRODATO Proizvod je rasprodat. Aktuelne proizvode iz ove kategorije možete pogledati klikom na dugme ispod: Vidi proizvode Dijamantske ploče Opis i namena proizvoda Motorni rezač EK8100 Makita Niska emisija izduvnih gasova prema 2002/88/EC za zaštitu životne sredine i povoljnosti za korisnika sa SLR tehnologijom Do 15% manja potrošnja goriva sa SLR tehnologijom Automatsko nivo gasa pri hladnom startu/sauh položaju Optimalan protok vazduha za hlađenje za dobro stanje pri teškim radnim uslovima Karakteristike proizvoda Prečnik diska ø 400 mm Prečnik nasadnog otvora diska ø 24,5 mm Maks. dubina sečenja 147 mm Konjska snaga 5,71 KS Snaga motora 4,2 kW Radna zapremina 81 cm³ Kapacitet rezervoara tečnosti za rasprskivanje 1,1 L Težina prema EPTA –i 10,6 kg 2-taktni motor Obim isporuke Brusni abrazivni disk

Tehnički podaci Preporučena dužina vodilice cm/inch 45cm/18″ Zapremina cm³ 72.2 Izlazna snaga kW/KS 3.9/5.3 Težina kg 1) 6.6 Odnos mase i snage kg/kW 2.0 Nivo zvučnog pritiska dB(A) 2) 103 Nivo snage zvuka dB(A) 2) 115 Vrednost vibracije levo/desno m/s² 3) 5.3/7.1 STIHL Oilomatic tip lanca testere 3/8″ P PM3 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 381 Robusna i pouzdana motorna testera gornje klase po snazi. Podnosi velika opterećenja i poseduje veliki obrtni moment. Dekompresioni ventil Ventil za dekompresiju je deo sistema za lako startovanje. Ventil treba pritisnuti pre startovanja da se smanji pritisak kompresije pri pokretanju kao i napor potreban da se povuče kanap startera. Ventil za dekompresiju je poluautomatski: kad se ručno pritisne pre paljenja automatski se zatvara kad motor upali. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugoročnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. Kompenzator Ovaj kontroler održava odnos gorivo/vazduh u smeši za sagorevanje konstantnim a otuda i snagu motora. Tacna količina goriva je dostavljena u karburator u zavisnosti od količine vazduha koji prolazi kroz filter za vazduh. Filter ne treba čistiti dok se ne pojavi znatan pad u snazi motora. Uljna pumpa sa regulacijomm kolicine Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Dekompresioni ventil Anti-vibracioni sistem STIHL Ematic sistem podmazivanja Kompenzator Uljna pumpa sa regulacijom količine Jednoručno rukovanje Zatezanje lanca sa strane Šifra proizvoda: ms-381 Kategorije: Motorne testere, STIHL, Za šumarstvo

filling capacity 750 kg max. workpiece height 900 x 300 mm workpiece weight total 550 kg max. workpiece weight 30 kg/Stck. revolutions per minute 22 U/min filling amount 50-60 % Colour blau 5015 RAL 0 1175 x 440 mm total power requirement 3 kW weight of the machine ca. 1995 kg dimensions of the machine ca. 2,9 x 1,33 x 1,75 m New deburring machine for safe and to efficiently deburr workpieces. Suitable for heavy applications. 6 - square drum lined with durable, vulcanized rubber thickness 36 mm, locking cover with gas pressure springs, roller shutters to protect againstthe rotating Container, stable design, easy operation. Control by timer on control surface, main and emergency stop switch. The maximum fillingquantity is 40% of the container volume and corresponds to 800 kg consisting of 500 kg workpieces + 300 kg deburring medium = hard manganese balls Pic 6 or cast iron pentagons Pic 7. These are over Sideros available. Stepless speed adjustment via frequency converter approx. 13-22 rpm (2850,-- ) Soundproof housing (65/70 Db) photo 7 and Sideros ECO B2 dust extraction against Available at extra cost. For complicated workpieces, the manufacturer recommends 100 kg sample parts of the material to be deburred to the factory for testing before ordering. VIDEO on our website. Machine dealer with own stock of 1600 m². The data for this ad was created with ModulMWS - the software solution of LogoTech oHG. Poruka Poruka

Opis proizvoda Do 20% manja potrošnja goriva i niska emisija izduvnih gasova prema 2002/88/EC za zaštitu životne sredine i povoljnosti za korisnika sa SAS-Tehnologijom EasyStart: lagani start sa automatskim blokiranjem na polovinu gasa Prekidač Touch&Stop – sa lakim dodirom prekidača, zaustavlja se motor i prekidač se automatski vraća u startni položaj, čime se eliminiše poplavljivanje karburatora Snabdevanje sa vodom sa usisnim filterom i fino podešavanje za adekvatnu zaštitu od prašine Vertikalni otvor za gorivo omogucava pristupacnije (lakse) sipanje Prozor za kontrolu nivoa goriva Vertikalni otvor za gorivo omogucava pristupacnije (lakse) sipanje Tehničke karakteristike Prečnik diska (Ø) 350 mm Unutrašnji prečnik (Ø) 200 mm Dubina sečenja 130 mm Motor 2-taktni motor Konjska snaga 4,3 KS Snaga motora 3,2 kW Radna zapremina 60,7 cm³ Kapac. rezervoаra zа gorivo 0,7 l Buka: zvučni pritisak 99,6 dB(A) Buka: zvučna snaga 108,6 dB(A) Buka: odstupanje (K) 2,5 dB(A) Vibracije: stražnja drška 3,5 m/s² Vibracije: prednja drška 2,7 m/s² Vibracije: odstupanje (K) 2,0 m/s² Težina prema EPTA –i 8,5 kg

Preis: Contact us for price Marke: RONZANI Pillow plate welding machine I.No. 1 CNC CONTROL DEVICE FOR WELDING STAINLESS STEEL PLATES WITH PLASMA AND TIG AUTOMATIC SYSTEM for the production of heat exchangers from steel sheet of up to 2000mm width with the following characteristics: reference Your drawing PUNTA20R6_L7 without Roller Conveyors and Applying Protection Film a. The plant positions the spot-welding units and the sheets to be both spot and edge welded. The welding units are carried on pneumatic driven slides for vertical travel and on two independent motorized axes for transversal-travel. Each axis carries two torches one for spot and transversal seam weld and the other for longitudinal seam weld The sheets are transferred by two couples of motorized rollers that allow sheets of considerable length to be processed with a minimum of 1600 mm b. An electronic device (PLC) controls the machine governing via the program the logical sequence of the processing cycle. The PLC is connected to a touch sensitive display terminal (Touch Screen) that allows the variable parameters for the single processes times and positions for welding to be input and memorized in the resident programs c. Two spot-welding and two continuous-welding units are provided each with a welding generator made up of a torch carriage with a special patented sheet holder for longitudinal transverse and spot welds d. N° 1 SCOTCH BRITE BRUSHING UNIT to clean the bottom side of dimple jacket from the welding’s oxide it is made the brushing unit inside of welding machine between the torch’s crossbeam and the output rubber roller. The unit moves transversely on carriage by pinion rack system to the vertical position controlling a pneumatic actuator rotates the brushing unit’s arm. The brushing is made by a scotch-brite dish e. N° 2 FRONIUS TT3000 JOB TIG generators for seam welds f. N° 2 SBI PLASMA SPOT WELDER PSW-500 V2.1 generators for spot welds g. Spot welding which employ two spot-welding units are carried out on a copper bar with cooling h. The longitudinal weld using two spot-welding units is effected on a copper roller i. The transversal weld will be done with one of two longitudinal torches 90° rotate j. The welding devices and accessories are carried at the side of the machine while the respective controls and electrical components will be installed in the electric panel k. The electrical energy supply rating is approximately 40 kW including the welding generators supplied at 400 Volt 3 phase 50 Hz plus neutral and ground l. No. 2 Remote Weld Monitoring Camera System with manual control for longitudinal and transverse seam weld on the edges of the jacket sheets m. The machine will be equipped with applications 1. No. 2 Application “Cold Wire System” for longitudinal and transverse seam welds 2. PUNTACAM APPLICATION. CAD-CAM software that allows to create the work program from a drawing file. With this application the machine is added of an industrial computer to work with Ronzani Puntacam software 3. ARCAM APPLICATION. Added to Puntacam software and special rotating equipment allows to make arcs and diagonal seam welds With this application the transversal seam weld will be done with one of two longitudinal torches 180° rotate All communication in panel will be prepared in Polish language GENERAL DESCRIPTION THE AUTOMATIC SYSTEM OF DIMPLE JACKET WELDING is suitable for working sheets up to 2000 mm wide and 6000 mm long with overall dimensions The machine has the following characteristics The automatic system of welding executes the positioning of the torches for the spot and seam weld around the border so as to form the dimple jacket structure. The torches are fixed on a pneumatic slide with pneumatic cylinders for vertical movement and on two motorized independent pneumatic slides for transversal movement. The sheets are moved by two pairs of motorized rolls which allow the processing of sheets of remarkable length. The minimal length is of 1600 mm The welding parameters are controlled by the PLC with a specific software that controls the operation schedule. The interface of communication between the operator and the machine consists of a touch screen control panel from which it is possible to select the position and the welding time programmable in a residential memory – copy to hard disc There are 2 working units with 2 generators. Two units are made up by 2 slides hold-torch with special equipment pressing sheet . The TIG torches groups can be turned by 180° to permit the transversal and longitudinal seam welding or diagonal and arc seam welding The Plasma spot welding is done on an inferior crosspiece that supports a branch bar with connection to ground and distribution of the protecting gas by cooling system. This crosspiece is lowered during the movement of the sheet to prevent damages on the inferior surface The continuous welding is done on a Copper and Aluminium roller with connection to ground the TIG torches can be turned by 180° on the roller to permit the transversal and longitudinal seam welding or diagonal and arc seam welding The components of welding are assembled under the roller conveyor The machine is provided by a monitoring system for the longitudinal and transversal welds this system has 3 cameras fixed on its support with optical screen photosensitive and two monitors located on the control board. The position of every single torch can be adjusted manually by 3 joysticks situated on the control pulpit Longitudinal and transversal seam welds can be realized on the edge of the sheet thanks to a monitoring system. The position of every single torch can be adjusted manually by 3 joysticks on the control pulpit System is working under control procedure and will switched off machine in below circumstances no power or any medium needed for process : electricity water cooling gas for TIG and PLASMA welding system II. TECHNICAL DATA OF MACHINE Machine is prepared for welding steels according group 8 9 10 Dimple jacket machine RONZANI Max sheet width 2000 mm Min sheet length 1600 mm Pillow plate thickness min 0.6 mm max 2.0 mm Base plate thickness min 1.0 mm max 20.0 mm Longitudinal Feeding sheet by 2 couples of rubber rollers Longitudinal Feeding sheet speed max 8 m/min Longitudinal Feeding Engine OMRON Sigma II 220 V 400W 1.27 Nm 3000 RPM N° Torch’s transversal carriage 2 (each carriage has 1 Plasma + 1 TIG) N° Plasma torches 2 N° Tig torches 2 Max transversal stroke for each carriage 1800 mm Transversal carriage speed max 8 m/min Transversal Feeding Engine OMRON Sigma II 220V 200W 0,637Nm 3000 RPM Lower side cooling bar: the copper bar has two different circuits the first with water-cooling circuit used to refrigerate the bar itself and the second with protection gas used to protect the dimple jacket during welding Water chiller HITEMA model ECA 001 Gas cooler generally mix Ar + CO2 copper bar length 2050 mm SBI PLASMA SOURCE DC PSW – 500 Supply voltage: 3x400V+N/50Hz Power connection: 5x32A CEE plug 6mm² Max. power consumption (50% on-time): 15kVA Cos ϕ : 0.99 Max. impulse current: 510A Degree of protection: IP23 dimensions (L x B x H): 1050x360x750mm weight: ca. 70kg Control range plasma gas 0.2 – 5 l/min Control range protective gas 0.2 – 20 l/min FRONIUS TIG SOURCE TransTig 3000 Job Main voltage 50 -60 Hz 3 x 400 V Main voltage tolerance +/- 15 % Main fuse protection (slow) 3 x 400 V 16 A Primary cont. power 3 x 400 V -100 % d.c. 6,1 kVA Cos phi 1 0.99 Welding current three-phase TIG 3 -300 Welding current three-phase MMA 10 -300 A Welding current single-phase TIG 3 -300 A Welding current single-phase MMA 10 -180 A Welding current at 10 min / 40 °C 50 % d.c. at 300 A Open-circuit voltage 85 V Standard working voltage TIG 10,1 -22,0 V Standard working voltage MMA 20,4 -32,0 V Ignition voltage (Up)* 10 kV Type of cooling / insulation class AF / B Dimensions l/w/h (inches) 22.0/9.8/17.1 Marks of conformity CE Protection IP 23 Lower brushing unit Travel length: 2100 mm Max work length: 2000 mm Feeding speed : min 2 max 9 m/min completely variable Pneumatic Slewing function max work pressure: 0,6 MPa Diameter of wheel: 250 mm Width of wheel: 100 mm Wheel rotation completely variable up to 3000 RPM Hood for dust suction Power of grinding motor: 3 kW 2poles 400V/50Hz 3 Phases Power of carriage motor: 1,1kW 4poles 400V/50Hz 3 Phases Control panel PLC programmable controller. All functions can be controlled separately Dimension: 1200 mm x 1100 mm x 1615 mm Remote assistance by Ethernet connection Computer Dell OptiPlex 780 or similar Software Cad/CAM EdgeCAM Milling Base Electrical features Operating Voltage and frequency 3 x 400Volt + N + PE- 50 Hz Installed power 35,0 kW Main switch 4 x 63A Electric line 5x16 mm2 Compressed Air Supply Pressure. 0.6 MPa (6 bar) Machine dimension Pass line: 915 mm Find more here pokazati kontakte Contact us at pokazati kontakte Poruka Poruka

Tehnički podaci Preporučena dužina vodilice cm/inch 45cm/18″ Zapremina cm³ 70.7 Izlazna snaga kW/KS 4.0/5.4 Težina kg 1) 6.3 Odnos mase i snage kg/kW 1.6 Nivo zvučnog pritiska dB(A) 2) 101 Nivo snage zvuka dB(A) 2) 112 Vrednost vibracije levo/desno m/s² 3) 4.2/4.5 STIHL Oilomatic tip lanca testere 3/8″ RS 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 440 Veoma dobro opremljena za seču u šumi srednjeg intenziteta i za seču velikog drveća. Sa pumpom za ulje sa regulacijom količine, STIHL ElastoStart mehanizmom za pokretanje sa uštedom snage, zatvaračem za rezervoar bez alata, radi jednostavnijeg i bezbednijeg punjenja gorivom i uljem, raspoloživ je mehanizam za adaptaciju na testeru za spasavanje. Dekompresioni ventil Ventil za dekompresiju je deo sistema za lako startovanje. Ventil treba pritisnuti pre startovanja da se smanji pritisak kompresije pri pokretanju kao i napor potreban da se povuče kanap startera. Ventil za dekompresiju je poluautomatski: kad se ručno pritisne pre paljenja automatski se zatvara kad motor upali. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugoročnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. Uljna pumpa sa regulacijomm količine Razlicite dužine reza, tehnike rada i vrste drveta zahtevaju rezličite količine ulja pri sečenju. Uljna pumpa sa regulacijom količine ulja omogućava korisniku da precizno podešava potrebnu količinu dovedenog ulja potrebnog za rad. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. Patent zatvarač Posebno posvećena pažnja na zatvarače rezervoara goriva i ulja za lako otvaranje i zaključavanje bez potrebe za alatom. Grejanje karburatora Promenom sa letnjeg režima rada na zimski, vazduh se prethodno zagreva preko rebara cilindra motora obezbeđujući da se karburator ne ledi na niskim temperaturama. Dekompresioni ventil Anti-vibracioni sistem STIHL Ematic sistem podmazivanja Uljna pumpa sa regulacijom količine Zatezanje lanca sa strane Jednoručno rukovanje Patent zatvarač Šifra proizvoda: ms-440 Kategorije: Motorne testere, STIHL, Za šumarstvo

Tehnički podaci Preporučena dužina vodilice cm/inch 45cm/18″ Zapremina cm³ 70.7 Izlazna snaga kW/KS 4.2/5.7 Težina kg 1) 6.6 Odnos mase i snage kg/kW 1.6 Nivo zvučnog pritiska dB(A) 2) 105 Nivo snage zvuka dB(A) 2) 117 Vrednost vibracije levo/desno m/s² 3) 3.1/3.3 STIHL Oilomatic tip lanca testere 3/8″ RS 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 441 Moderna, vibracijama siromašna, snažna testera za šumarstvo. Sa 2-MIX motorom koji čuva životnu sredinu i sa savremenim AV-sistemom. Ima dugotrajni filter sistem sa predčišćenjem i poboljšani odnos između snage i mase. Ima 20% manju potrošnju goriva i 70% manje štetnih materija u izduvnim gasovima od testera iste snage. Dekompresioni ventil Ventil za dekompresiju je deo sistema za lako startovanje. Ventil treba pritisnuti pre startovanja da se smanji pritisak kompresije pri pokretanju kao i napor potreban da se povuče kanap startera. Ventil za dekompresiju je poluautomatski: kad se ručno pritisne pre paljenja automatski se zatvara kad motor upali. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugorocnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. Uljna pumpa sa regulacijomm količine Različite dužine reza, tehnike rada i vrste drveta zahtevaju rezličite kolicine ulja pri sečenju. Uljna pumpa sa regulacijom količine ulja omogućava korisniku da precizno podešava potrebnu količinu dovedenog ulja potrebnog za rad. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. Patent zatvarač Posebno posvećena pažnja na zatvarače rezervoara goriva i ulja za lako otvaranje i zaključavanje bez potrebe za alatom. Grejanje karburatora Promenom sa letnjeg režima rada na zimski, vazduh se prethodno zagreva preko rebara cilindra motora obezbeđujući da se karburator ne ledi na niskim temperaturama. Dekompresioni ventil Anti-vibracioni sistem STIHL Ematic sistem podmazivanja Uljna pumpa sa regulacijom količine Zatezanje lanca sa strane Jednoručno rukovanje Patent zatvarač Šifra proizvoda: 11382000014 Kategorije: Motorne testere, STIHL, Za šumarstvo

Tehnički podaci Preporučena dužina vodilice cm/inch 45cm/18″ Zapremina cm³ 76.5 Izlazna snaga kW/KS 4.4/6.0 Težina kg 1) 6.7 Odnos mase i snage kg/kW 1.5 Nivo zvučnog pritiska dB(A) 2) 105 Nivo snage zvuka dB(A) 2) 117 Vrednost vibracije levo/desno m/s² 3) 4.0/3.8 STIHL Oilomatic tip lanca testere 3/8″ RS 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 461 Nova, veoma snažna motorna testera za secu u srednje teškim i teškim predelima. Zamena za dokazani model MS 460. Sa novim 2-MIX motorom, koji ima smanjenu potrošnju goriva i nižu emisiju izduvnih gasova, te osetno bolji rast obrtnog momenta. Standardno je opremljena sa dugotrajnim HD2 filterom i vecom ubodnom lajsnom za bolju kontrolu kod dubokog rezanja. Dekompresioni ventil Ventil za dekompresiju je deo sistema za lako startovanje. Ventil treba pritisnuti pre startovanja da se smanji pritisak kompresije pri pokretanju kao i napor potreban da se povuče kanap startera. Ventil za dekompresiju je poluautomatski: kad se ručno pritisne pre paljenja automatski se zatvara kad motor upali. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugorocnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. Uljna pumpa sa regulacijomm količine Različite dužine reza, tehnike rada i vrste drveta zahtevaju rezličite kolicine ulja pri sečenju. Uljna pumpa sa regulacijom količine ulja omogućava korisniku da precizno podešava potrebnu količinu dovedenog ulja potrebnog za rad. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. Patent zatvarač Posebno posvećena pažnja na zatvarače rezervoara goriva i ulja za lako otvaranje i zaključavanje bez potrebe za alatom. Grejanje karburatora Promenom sa letnjeg režima rada na zimski, vazduh se prethodno zagreva preko rebara cilindra motora obezbeđujući da se karburator ne ledi na niskim temperaturama. Dekompresioni ventil Anti-vibracioni sistem STIHL Ematic sistem podmazivanja Uljna pumpa sa regulacijom količine Zatezanje lanca sa strane Jednoručno rukovanje Patent zatvarač Šifra proizvoda: ms-461 Kategorije: Motorne testere, STIHL, Za šumarstvo

Tehnički podaci Preporučena dužina vodilice cm/inch 30cm/12″ Zapremina cm³ 30.1 Izlazna snaga kW/KS 1.3/1.8 Težina kg 1) 3.1 Odnos mase i snage kg/kW 2.4 Nivo zvučnog pritiska dB(A) 2) 97 Nivo snage zvuka dB(A) 2) 112 Vrednost vibracije levo/desno m/s² 3) 2.9/3.1 STIHL Oilomatic tip lanca testere 3/8″ P PMM3 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 193 T Nova STIHL MS 193 T motorna testera je savršen partner u teškim poslovima održavanja drveća duž puta ili u parkovima i voćnjacima. Ona kombinuje izvanredne performanse sa malom težinom i bezkompromisnom udobnosti za korisnika. MS 193 T je specijalno dizajnirana za rad među granama i treba da je koriste samo obučeni stručnjaci za šumarstvo. STIHL 2-MIX motor Dvotaktni motor sa 2-MIX tehnologijom daje dobre rezultate, veliku vučnu snagu, a pri tom štedi i do 20% goriva u poređenju sa dvotaktnim motorima iste snage, bez 2-MIX tehnologije. Rasklopiva kuka Rasklopiva kuka služi kao prilog za kačenje kanapa radi sigurnijeg podizanja i spuštanja testere. Kad je u sklopljenom položaju ne smeta pri radu i skladištenju. Napredna tehnologija sagorevanja Četiri prelivna kanala vrte smešu benzina i vazduha pre paljenja, omogućavajući optimalno sagorevanje i visoko efikasne performanse. Rezultat je manja potrošnja goriva i visok obrtni momenat u širokom opsegu obrtaja. Integrisane matice Prilikom zamene reznog alata nema rizika od gubitka matica lančanika. Velika prednost za sve korisnike. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugoročnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. Kompenzator Ovaj kontroler održava odnos gorivo/vazduh u smeši za sagorevanje konstantnim a otuda i snagu motora. Tačna količina goriva je dostavljena u karburator u zavisnosti od količine vazduha koji prolazi kroz filter za vazduh. Filter ne treba čistiti dok se ne pojavi znatan pad u snazi motora. Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Patent zatvarač Posebno posvećena pažnja na zatvarače rezervoara goriva i ulja za lako otvaranje i zaključavanje bez potrebe za alatom. Šifra proizvoda: MS193-T Kategorije: Motorne testere, Specijalne testere, STIHL

Tehnički podaci Preporučena dužina vodilice cm/inch 45cm/18″ Zapremina cm³ 72.2 Izlazna snaga kW/KS 3.9/5.3 Težina kg 1) 6.6 Odnos mase i snage kg/kW 2.0 Nivo zvučnog pritiska dB(A) 2) 103 Nivo snage zvuka dB(A) 2) 115 Vrednost vibracije levo/desno m/s² 3) 5.3/7.1 STIHL Oilomatic tip lanca testere 3/8″ P PM3 1) Sa praznim rezervoarima, bez vodilice i lanca 2) K-factor prema DIR 2006/42/EC = 2.5 dB (A) 3) K-factor prema DIR 2006/42/EC = 2m / s ² Specifični detalji mogu biti podložni promenama bez prethodne najave. STIHL MS 382 Dekompresioni ventil Ventil za dekompresiju je deo sistema za lako startovanje. Ventil treba pritisnuti pre startovanja da se smanji pritisak kompresije pri pokretanju kao i napor potreban da se povuče kanap startera. Ventil za dekompresiju je poluautomatski: kad se ručno pritisne pre paljenja automatski se zatvara kad motor upali. Anti-vibracioni sistem Intenzivne vibracije na ručkama mogu dovesti do dugoročnih posledica na krvne sudove u šakama i rukama. STIHL je stoga razvio delotvoran anti-vibracioni sistem gde egzaktno proračunate odbojne zone smanjuju prenos oscilacija motora i lanca testere na cevi držaca i ručke. STIHL Ematic sistem podmazivanja STIHL Ematic sistem umanjuje potrošnju ulja za podmazivanje lanca i do 50% u poređenju sa konvencionalnim vodilicama bez Ematic sistema, u zavisnosti od kompleta za sečenje i vrste materijala koji se seče. Sistem se sastoji od STIHL Ematic ili Ematic S vodilice, STIHL Oilomatic lanca testere i pumpe za ulje sa regulatorom potrošnje tj. smanjenom potrošnjom ulja. Ulje za podmazivanje lanca ciljano se usmerava tamo gde je potrebno i uz najmanju potrošnju. STIHL ElastoStart Kod motora s unutrašnjim sagorijevanjem usled kompresije u cilindru stvara se otpor prilikom procesa pokretanja motora. Stihl ElastoStart je specijalna ručica koja omogućava ravnomeran postupak pokretanja bez naglog pojavljivanja vršne snage. Intergrisani amortizacijski element pritom izravna tok snage koji nastaje prilikom pokretanja. Na takav način znatno se olakšava postupak pokretanja. Zatezanje lanca sa strane Udoban način zatezanja lanca na bezbednom odstojanju od oštrice lanca. Uljna pumpa sa regulacijomm količine Različite dužine reza, tehnike rada i vrste drveta zahtevaju rezličite količine ulja pri sečenju. Uljna pumpa sa regulacijom količine ulja omogućava korisniku da precizno podešava potrebnu količinu dovedenog ulja potrebnog za rad. Jednoručno rukovanje Svim važnim funkcijama kao što su start, saug, gas i stop, može da se upravlja jednom rukom. Kompenzator Ovaj kontroler održava odnos gorivo/vazduh u smeši za sagorevanje konstantnim a otuda i snagu motora. Tacna količina goriva je dostavljena u karburator u zavisnosti od količine vazduha koji prolazi kroz filter za vazduh. Filter ne treba čistiti dok se ne pojavi znatan pad u snazi motora. Dekompresioni ventil Anti-vibracioni sistem STIHL Ematic sistem podmazivanja STIHL ElastoStart Zatezanje lanca sa strane Uljna pumpa sa regulacijom količine Jednoručno rukovanje Kompenzator Šifra proizvoda: 11192000266 Kategorije: Motorne testere, STIHL, Za šumarstvo

New CNC laser chillers for sale Lasertech challenges four major issues in a laser machine cooling system Providing two different temperatures to cool resonator and laser heat exchanger. Precision of the water temperature +/-1°C The compatibility of the hydraulic circuit with very low conductivity water. Deionization of the water Whether it is for CO2 lasers or fiber lasers Lasertech is the correct choice. When it comes to precise temperature control for your resonator and optics Lasertech has a complete line of industrial laser chillers to meet your requirements Precise cooling for the resonator and optics circuit Single or Dual temperature for resonator and optic circuits Cooling range from 0.8 kW to 116 kW Stainless Steel circuit design Conductivity Measurement Deionization filtering system optional Dual Pump Configuration PLC touch pad control Set point regulation based on return water temperature R-410 gas standart and R-134 for hot climates Modbus communication interface between Laser tech & your machine Customise able to meet your specific requirement Your cooling specialist for industrial application Laser technology Machine tools Plastics industry Printing industry Surface technology Packaging industry PC SERIES: CHILLERS FOR INDUSTRIAL COOLING (1-226KW) All cooling block systems are compact factory-assembled condensing units suitable for an immense range of industrial applications. All devices comply with multiple regulations including EC directives standards and provisions: ISO 9001 EN 378 VDE and BGV Industrial cnc laser chillers suitable for 1kw 1.5kw 2kw 2.2kw 2.5kw 2.6kw 2.8kw 3kw 3.5kw 3.8kw 4kw 4.4kw 5kw 5.2kw 6kw 8kw and 10kw cnc lasers for sale RIEDEL chiller for sale EF Chiller for sale Stacker chiller for sale Tricool chiller for sale Donaldson chiller for sale Chillers for sale suitable for Trumpf Amada Bystronic Prima Mazak and Lvd lasers Customer built at competitive price Cnc laser cooling solutions Chillers that can be made to same specification as the following chillers commonly used on Trumpf Amada and Bystronic lasers KKW Reidel PC 200.00 chiller Donaldson UC-300SP Riedel Series 1001 Tricool 2152 – 50 AMS Tricool 21 series S2/120 can be made as a new chiller Tricool 21 series S2/145 Tricool 2152 – 50 AMS Tricool KKW Riedel PC80.01-NE Lasertech challenges four major issues in a laser machine cooling system Providing two different temperatures to cool resonator and laser heat exchanger. Precision of the water temperature +/-1°C The compatibility of the hydraulic circuit with very low conductivity water. Deionization of the water Whether it is for CO2 lasers or fiber lasers Lasertech is the correct choice. When it comes to precise temperature control for your resonator and optics Lasertech has a complete line of industrial laser chillers to meet your requiremens. Precise cooling for the resonator and optics circuit Single or Dual temperature for resonator and optic circuits. Cooling range from 0,8 kW to 116 kW Stainless Steel circuit design Conductivity Measurement Deionization filtering system optional Dual Pump Configuration PLC touch pad control Setpoint regulation based on return water temperature R-410 gas standart and R-134 for hot climates Modbus communication interface between Lasertech & your machine Customizable to meet your specific requirement LTC MODEL MINI MIDI LTC 104 Cooling Capacity 1000 1500 2000 3000 6.000 10000 18000 25000 30000 40000 50000 61000 80000 104000 Type 1 1 1 1 1 1 1 1 1 2 2 2 2 2 n° Piston Scroll Scroll Absorbed Power (Kw) / Gezogene Leistung (Kw) 0,33 0,55 0,4 0,7 1,4 1,92 3,24 4,3 5,9 6,48 8,78 12,3 15,3 19,3 Fan / Ventilator n° 1 1 1 1 1 1 1 1 1 1 1 1 2 2 Power (W) / Leistung (W) 100 100 100 180 180 220 220 680 1100 1800 1800 1800 3600 3600 Diameter (mm) / Durchmesser (mm) – – 300 450 180 500 500 630 710 800 800 800 800 800 Water Pump Power (Hp) / Leistung (Hp) 0,5 0,5 0,5 0,5 0,5 1 1 1 2 2 3 3 4 4 Maksimum Flow (it/min.) / Maximaler Durchfluss (l/min.) – – 40 40 40 100 100 100 220 220 240 240 450 450 Maksimum Pressure (bar) / Maximaler Druck (bar) – – 3,8 3,8 3,8 3,3 3,3 3,3 3,3 3,3 3,3 3,3 3,3 3,3 Water Tank Litre 15 15 25 70 70 70 120 130 200 200 200 350 350 350 Cnc laser spare part chiller for sale Tropical chillers available for sale for extreme heat Industrial chilling units for sale Poruka Poruka

PRODATO Proizvod je rasprodat. Aktuelne proizvode iz ove kategorije možete pogledati klikom na dugme ispod: Vidi proizvode Punjači i baterije za akumulatorski alat Opis i namena proizvoda Echo akumulatorski trimer za travu DSRM-2600/U DSRM-2600 akumulatorski trimer je dizajniran za rad na profesionalnom nivou. Motor bez četkica nudi snagu ekvivalentnu benzinskom motoru od 25 cm³, kombinujte ovo sa savršenom ravnotežom i nizom funkcija za udobnost i imate alat koji je prikladan za lakše obavljanje velikih poslova. Sekvencijalna kontrola brzine u 3 koraka i poluga gasa nalik na motor daju precizno sečenje i napravljeni su za brzu reakciju koja se oseća kao alat na benzin. Sa težinom od samo 3,7 kg, to je najlakša motorna kosa u svojoj klasi i sa savršenim centrom ravnoteže imate alat koji je izuzetno upravljiv i udoban za upotrebu tokom dugih vremenskih perioda. Performanse poput benzina. Poseduje napredni motor sa spoljnim rotorom, koji je male težine i pruža visoku snagu koja se može uporediti sa motornom motornom motornom motornom kosom od 25 cm³. Rotor generiše veliku dinamičku silu, baš kao zamajac na benzinskom motoru, što održava mašinu da radi glatko i nesmetano, čak i kada se radi o dugoj travi ili gustom grmlju. Najlakši u svojoj klasi. DSRM-2600 aku trimer je lagan, ali robustan.U stvari, sa samo 3,7 kg, najlakši je u svojoj klasi, što znači da u pogledu odnosa snage i težine nadmašuje motorne kose od 25 cm³. Vreme rada Funkcija koja se zove ECO režim obezbeđuje da se energija ne gubi i da se koristi kada je najpotrebnija, dajući DSRM-2600 procenjeno vreme rada od oko 30 minuta neprekidnog korišćenja na najvećoj snazi (sa LBP-560-200). Karakteristike proizvoda Tip baterije: Li-ion Napon: 50.4 V Radni zahvat niti: 430 mm Autonomija 2.3Ah (min): 30 min Autonomija 4.5Ah (min): 60 min Težina bez baterije: 3.7 kg Obim isporuke Isporučuje se bez baterije i punjača

-

Mašine i alati chevron_right Građevinske mašine

ZOOMLION HBT80.16.174RSU 2018 【ACHIEVE】TOP CONDITION!!! Stationary concrete pump 3.1.1 Intelligent control system The first use of the industrial controller with self diagnosis and protection function make the machine more stable and reliable. Configuration of the touch screen, real-time monitoring of operating conditions, parameter settings, query historical data, view the fault records and maintenance skills. The cabinet switchs are configuraed all the features of the label, easy function expansion. The installation of stroke control and flexible reversing, the concrete cylinder stroke more in place, the suction is more strong, and the impact is less. 3.1.2 Main technical highlights Flexible reversing technique: Monitore the whole pumping conditions. Automaticly adjust the various mechanism to achieve smooth pumping of concrete without impact, improve the pumping efficiency, and extend the hydraulic parts’ and structural parts’ life. Best time difference logic reversing technique: The main cylinder reversing and S valve change-over time is in the best state. The reversing impact is small, and the components’ life is longer. Full stroke control technique: Ensure that the pumping cylinder piston stroke in place at the same time, to ensure that the concrete piston stroke in place, suction efficiency is higher; double signal control, higher reliability. Engine start: According to the rotation speed and the starting time, the utility model can automatically close or cut off the starting circuit, and the operation is convenient. This can 3 / 14 effectively protect the starting motor of the diesel engine and prolong the service life of the diesel engine. Adaptive variable power technology: Improve the pumping capacity. According to the concrete conditions and pumping conditions, so that the engine is always working at the best load rate, to ensure that it works in the economic fuel consumption area. 3.2 Pumping unit 3.2.1 Using the finite element analysis software, the strength and stiffness of the main components of the pumping unit under different working conditions are analyzed and calculated. At the same time, the fluid simulation of the concrete in the hopper and the concrete cylinder is carried out, and the pumping unit suction efficiency is higher than the industry average of 10%. 3.2.2The agitator mechanism adopts a new double lip sealing mode, which has the advantages of simple structure and long service life. The sealing shaft is provided with an alloy wear-resistant sleeve. The Zoomlion patent has a new agitator sealing structure and sealing agitator blade. The lower failure rate is now 0.3% from the original 7.6%, only 3.9% of the old structures; agitator blade appearance, low cost, long service life. 3.2.3 High technical performance: pumping system uses the large displacement pump oil. Not only improve the reliability of the equipment, but also better performance. Pumping curve is below: Pumping output-pressure curve Low pressure pumping High pressure pumping Pumping pressure bar 4 / 14 Pumping output m /h ³ 3.2.4 High reliability: Hydraulic components and electrical components are internationally famous brand products, coupled with excellent system design, so that the reliability of the pumping system is high, and the use of low cost. 3.3 Hydraulic system 3.3.1 Dual pump dual circuit hydraulic system The pump hydraulic system adopts the large displacement open or closed plunger pump and the main oil cylinder to form an independent pumping circuit. The distribution hydraulic system is composed of a high performance constant pressure pump and a distributing cylinder. The pumping oil circuit and the distribution oil circuit cooperate with each other and do not interfere with each other. The special flexible commutation technology makes the hydraulic impact smaller, and the system component has a longer service life. The double circuit design is easy to realize the logic control, the performance is reliable, and it is easy to update the update control function. 3.3.2 Fluid simulation design of hydraulic system Use fluid simulation software to simulate the hydraulic system. The various components of the hydraulic system reach the most reasonable match with the simulation, and optimizate the hydraulic system. 5 / 14 3.4 Electric control system Outstanding feature of the electric control system is advanced in technology, simple operation, high reliability. 3.4.1 The IMF, German industrial controller, with the CAN or the Emerson, America brand programmable controller, as the control core, high reliability and powerful function; reduce the fault point, and improve the reliability of the electronic control system. 3.4.2 Electrical components using France Schneider, Panasonic and other imported components, to ensure the high reliability. 3.4.3 Wired remote control mode, and operate more convenient. 3.4.4 The electric control display screen monitors the real-time working condition, the fault alarm. The equipment operation monitoring, the maintenance and the maintenance operation is more convenient. 3.5 Cooling system The system circuit adopts a forced cooling device, and the working oil temperature is 70 degrees, to ensure the normal work. Water cooling system can be selected according to user requirements. 3.6 Power system Assembly of Deutz (Dalian) BF6M1013 series engine, the electronic unit pump and external 6 / 14 exhaust gas recirculation technology, exhaust emission limits conform to the three phase of the national emission standards requirements. The real-time CAN line monitoring engine condition. the engine control unit (ECU) according to different conditions, can provide the best air-fuel ratio and the optimal ignition time to the engine, the engine power, economy and emission of the best. Intelligent diagnosis and emergency function to ensure timely troubleshooting and effective protection of the engine. Poruka Poruka

Preis: Contact us for price Marke: Adue SYRUP ROOM PROCESS PLANT SUITABALE FOR JUICE PRODUCTION Check PDF on website to download infos 4000 liter an hour - There are 2x Plants available (so 8000 liters an hour of juice production) there is a water treatment plnt (12.000 liter/hour) At the end of the line there is a Flash pasteurizer CIP also included Can produce yoghurt ice cream any beverage TO BE HOT FILLED CAPABLE TO FEED nr. 4 FILLING LINE WITH FLOW RATE 1.500 l/h EACH FOR A TOTAL FLOW RATE OF 6.000 l/h OF FINAL BEVERAGE Product specification In case of ordering detailed specification of all products are immediately required if possible together with products samples The nominal outputs of the proposed plants and machinery are based on the so-called non-problematic products without major foaming such as fruit juices fruit juices drinks milk based products. High viscosity products or strongly foaming products may require reduction of the nominal output of the proposed plants and machinery Project planning The installation of the proposed plants and machinery is done on the basis of an installation plan made by ADUE in close cooperation with the Customer and which requires the Customer’s final approval. ADUE will supply the required documentation for the planning stage In case of considerable layout changes requested after the Customer’s final approval ADUE reserves the right to invoice the additional costs to the Customer Room Temperature Parameter min. max. Unit Temperature 15 35 °C Humidity 30 70 % If temperature is higher all control boards must be equipped with Air Conditioning Units against extra cost Ambient Temperature Parameter min. max. Unit Temperature -15 50 °C Humidity 30 90 % Commissioning and Start up The proposed plants and machinery will be commissioned by ADUE with 3 test productions together with fillers immediately after the completion of erection As soon as laboratory results are available the start-up phase will be done with products and capacities specified by the Customer in a 10 – shift production each shift consisting of 8 hours ( 1 shift / day ) SUGGESTED WATER CHARACTERISTICS 1. Drinking water (mains water) The drinking water should also be used as cleaning water and product flush water The quality should meet the WHO guidelines (stated below) or European EC drinking water directive Taste none Smell none Turbidity max 3 NTU Colour max 20 mg/l Pt Oxygen demand max 20 mg/l KNnO4 Total dissolved solids max 500 mg/l pH (M,S) 7-8.5 Total hardness (M,S) 4-7 dH Ammonium traces Ammonia max 0.5 mg/l NH4 Iron max 0.1 mg/l Fo Manganese max 0.05 mg/l Mn Nitrate max 30 mg/l NO3 Nitrite max 0.02 mg/l NO2 Sulphate max 100 mg/l SO4 Chlorine (M,S) max 0.2 mg/l Cl2 Chloride (M,S) max 30 mg/l Cl Aggressive corbon acid max 0 mg/l CO2 Corbon acid (M,S) Total amount of bacteria max 100/ml Total amount of 35°C coliform bacteria max 1/100 ml Total amount of 44°C coliform bacteria 0/100 ml Copper max 0.05 mg/l Cu Zinc max 1.0 mg/l Zn In addition Design pressure 300 kPa Temperature 15°C Capacity m3/h: AS PER QUOTATION 2. Product water is used for reconstitution of product concentrates Product water may not affect the essential characteristics of the product and its minimum requirement should follow the EC drinking water directive The reference temperature is 20 - 30°C This means for example Conductivity max 400 us/cm Chloride max 25 mg/l Cl Sulphate max 25 mg/l SO4 Calcium max 100 mg/l Ca Sodium max 20 mg/l No Nitrate max 25 mg/l NO3 3 Service water to be used as cooling water sealing water tower water and boiler feed water There are different requirements for all the different types of service water Special attention must always be taken to hardness (CaCO3) chlorine chloride and pH. The service water shall be without solid particles If unclear requirements we recommend to use the same quality demands as for mains water Boiler feedwater Hardness max 0.1 dH Rest aluminium max 0.2 mg/l pH 8.5-9 Silicon acid max 30 mg/l SiO2 Tower water Design pressure 300 kPa Capacity m3/h: AS PER QUOTATION Temperature °C: AS PER QUOTATION Cooling water Design pressure 300 kPa (e) Capacity m3/h: AS PER QUOTATION Temperature °C: AS PER QUOTATION Ice water Design pressure 300 kPa Capacity m3/h: AS PER QUOTATION Temperature °C: AS PER QUOTATION 4 Suggested steam characteristics Main advices Steam has to be of good quality and dry Steam feeding piping has to be equipped with a pressure regulator in order to keep a constant feeding pressure Steam piping has to be insulated in order to avoid to hurt people The main features are the following Pressure: min 3 bar – max 8 bar Quality: dry saturated steam Humidity : max. 5% of condensate Max pressure of condensate recovery: 0,5 Bar 5 Suggested electricity characteristics The following network has to be distributed in the factory Voltage : 230/ 400 V Frequency : 50 Hz Voltage variation : max. ± 5% Frequency variation: max. ±-2% Phases : 3 + neutral Auxiliary : 24 V – AC/DC Environment information The factory is located in Lagos - Nigeria altitude on sl less than 400 m Rules and Standards Electric principle IEC (International Electrotecnic Commission) Measurement SI (Unit International System) Mechanic EN and UNI norms Electric EN 60204 Tank under pressure 97/23/CE Equipment protection degree proposed: IP 54 A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.20135 6 Suggested compressed air characteristics The main characteristics are the following ones Pressure : 6 - 8 bar Quality : dry and non-oiled air Water content : none Oil content : max. 10mg/l Dew point : min. 10°C less than ambient temperature Solid particles : max. 0.01 A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 6 SUPPLY DESCRIPTION SUGAR - THICKENERS - MINOR COMPONENTS & LIQUIDS INGREDIENTS PREPARATION SECTION POS.1 N.2 MAGNETIC FLOW METER Magnetic flow meter suitable to control the process water quantity transferred to the blending tanks the dissolving tank and to the acid and minor ingredient storage/dissolving tanks Minimum conductivity > 50 µS/cm POS.2 N.2 DISSOLVER DR 10 Suitable to dissolve sugar & powders completely built in stainless steel equipped with Stainless steel skid in Aisi 304 tickness.40/10 n° 04 adjustable stainless steel supporting feet Removable bag holder Suction regulation manual butterfly valve Dn50 with 9 postions Inlet/Outlet of the liquid with connection Dn50 F Mixing chamber type “Double Vacuum” Pump 4 Kw Carter to cover the pump body Stainless steel hopper supporting frame Switch control system with termic to protect the motor Overall dimension: 1000x800x H=900 mm Weight: Kg 95 A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 7 Technical Features Pump capacity: 15 m³/h Product Viscosity: ± 100 CPS Specific gravity: 1,2 Product Temperature: +2°/+80°C Dissolution capacity: 1000 Kg/h * Power supply: Multi-voltage Volt 380/660 Hz. 50 Injector : Made in non-toxic resin Vacuum degree: -0,7 Bar N.B.: All the parts in contact with the product are in stainless steel AISI 316 L the other parts are in stainless steel AISI 304 POS. 3 N.2 STORAGE/DISSOLVING TANKS Storage tanks cap. 2.000 L. each on vertical axis closed shape equipped with agitator suitable for Sugar Thickeners powders & liquids dissolution built in AISI 316 stainless steel equipped with n.4 adjustable stainless steel supporting feet High efficiency Turbo Emulsifier agitator group on vertical axis service connections spray washing ball group with DN 40 connection POS.4 N.1 BAG FILTERS Bag filters flow rate 6.000 l/h for sugar syrup at 50°Bx and 25°C A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 8 BLENDING SECTION POS.5 N.4 BLENDING TANKS type S cap. 6.000 L each one on vertical axis closed shape built in AISI 316 stainless steel The tanks are used to prepare the juice concentrate to feed the Blending Thanks Each tank is equipped with conical type bottom and lid electro stirrer group on vertical axis n.5 adjustable stainless steel supporting feet DN 400 quick-locking inspection manhole placed on the top service connections spray washing ball group with DN 40 connection stainless steel air vent level probe Finishing welds executed in Argon inter gas atmosphere with the TIG method inner welds ground and satin outer welds ground and satin cold rolled with 2B finishing externally cold rolled with 2B finishing internally A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 9 POS.6 N.2 SWING BEND PANELS To serve the two above mentioned Blending Tanks suitable to load the ingredients into the blending tanks to feed the product to the Premix for washing solutions recovery The swing bend panels includes frame built in AISI 304 stainless steel Automatic butterfly valves in AISI 316 stainless steel connections connection to the tanks POS.7 N.2 CENTRIFUGAL ELECTROPUMP to feed the Pasteurizer built in AISI 316 stainless steel flow rate 3.000 l/h each POS.8 N.2 SELF-PRIMPING CENTRIFUGAL ELECTROPUMP for washing solutions recovery built in AISI 316 stainless steel flow rate 20.000 l/ each POS.9 N.1 SERVICE LADDER To serve the two Blending Tank in case of maintenance and inspections A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 10 TUBULAR PRE HEATER / COOLER SECTION POS.10 N.2 HOT FILLING TUBULAR HEATER / COOLER FOR STILL DRINK FLOW RATE 3.000 L/H EACH FOR A TOTAL OF 6.000 L/H OF FINAL BEVERAGE EACH MACHINE IS CAPABLE TO FEED NR. 2 FILLERS AT THE SAME TIME FOR A TOTAL RUNNING OF 4 FILLERS SIMULTANEOUSLY The Plant Is Composed By N.1 MULTI-PIPE HEAT EXCHANGER TWO STAGE suitable to pasteurise with the following cycle pre – heating stage from +20°C to +85°C by means of hot water circulation cooling stage from 85 to 45°C for the product recycling from the filler by means of tower water The equipment is composed by stainless steel supporting frame for tubular elements multi-pipe tubular exchanging elements sanitary type with pipe for product passage in AISI 316 L equipped with expanding compensator thermometers and PT100 for working temperature control Stainless Steel Piping Including: pipes fittings valves manual and automatic valves deviating valves etc A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 11 N.1 OVER-HEATED WATER PREPARATION AND CIRCULATION SYSTEM at 98÷100°C servicing the pasteurisation stage fully built in stainless steel including: heat exchanger water/steam without direct injection of steam in water circulation centrifugal pump for water built in stainless steel modulating pneumatic valve for the regular inlet of dry saturated steam at 4 Bar pressure reducer steam filter manual on/off valve pressure gauges steam trap hot/over-heated water connecting pipes between water preparer and tubular elements including expanding small tank safety valve pressure gauge thermometer N.1 CONTROL PANEL AND INSTRUMENTS including PLC SIEMENS S7 to control the pasteurisation cycles equipped with software and operational keyboard TP270 - Siemens Panel in stainless steel hinged front door waterproof equipped with external air conditioner Electrical part for protection and control auxiliary circuits 24V silent key auto/manual deviator Working circuit to select production/washing/sterilisation The panel is placed on the en bloc base INSTRUMENTS for an automatic control recording of the pasteurisation temperature including Temperature regulator range 10÷140°C stainless steel probes and equipped with intervention contact in case of low temperature Filter/reducer for instruments service compressed air with fittings and pipe for reduced compressed air distribution Reducer for service compressed air Solenoid valves for air Process Description The pasteurizer start up is with product. When the pasteurization temperature is reached the system gives to filler the readiness signal. In case of line stop after a settable time the pasteurizer stops the steam feeding keeping the product in recirculation with cooling section on to cool down the product avoiding cooking and related damages When filling line is ready the pasteurizer start feeding steam till the pasteurization temperature is reached again. When product from one batch tank is finished the pasteurizer stops giving indication to operator (alarm) to change the swing bend panels. To go back to production the operator confirm operation done A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 12 SANIFICATION SECTION POS.11 N.1 “CIP UNIT 3 x 2.000 L” SANITIZING EQUIPMENT Automatic running equipped with n°1 washing manifolds composed by N.1 Insulated section for the preparation of soda solution capacity 2.000 l cylindrical shape built in AISI 304 stainless steel equipped with insulation on the cylindrical band level probe group inspection manhole stainless steel adjustable supporting feet safety overflow pipe outside the tank with a minimum diameter of 80 mm service connections finish: internally and externally 2B rolled with ground and satin welds N.1 Insulated section for hot water capacity 2.000 l cylindrical shape built in AISI 304 stainless steel equipped with insulation on the cylindrical band level probe group inspection manhole placed on the lid stainless steel adjustable supporting feet safety overflow pipe outside the tank with a minimum diameter of 80 mm service connections finish: internally and externally 2B rolled with ground and satin welds A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 13 N.1 Not insulated section for water recovery capacity 2.000 l cylindrical shape built in AISI 304 stainless steel equipped with level probe group inspection manhole placed on the lid stainless steel adjustable supporting feet safety overflow pipe outside the tank with a minimum diameter of 80 mm service connections finish: internally and externally 2B rolled with ground and satin welds n°1 on-line conductivity meters to automatically recover the soda solution with a % data readout & to control the washing solution recovery temperature n°1 PT 100 to control the washing solution delivery temperature n°1 thermometers to control the washing solution delivery temperature n°1 pressure gauges to control the washing solution delivery pressure Inlet valves of 20,000 l/h of cold water at 7/8 bar to rinse directly the utilities to be washed cold water SUPPLIED BY THE CUSTOMER n°1 centrifugal pump sanitary type for washing solution feeding flow rate 20.000 l/h - 2,5 bar equipped with frequency converter n°1 diaphragm electro pump to dose/transfer the caustic soda concentrate n°1 diaphragm electro pump for the In-Line dosing of the disinfectant solution n°1 magnetic flow meter for washing flow rate control n°1 tubular heat exchangers of 500,000 Kcal/h each (maximum steam consumption 1.000 kg/h at 4 bar) built completely in stainless steel Aisi 316 equipped with a modulating valve to adjust the steam a steam trap pressure gauges and a thermo regulator to control the temperature. The exchangers are used to heat on recirculation (inside CIP tanks) the caustic soda solution (or water) from room temperature to +85°C approx. during the setting the CIP unit to optimum working conditions. They are also used to keep the washing solution at the temperature of +85°C approx. during the washing program A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 14 N.1 Electro-Pneumatic Control Board For the automatic management of the section including SIEMENS S7 ‘PLC’ electric and pneumatic instruments to control the processing data to control and protect the motors for the signal exchange managing for the integration with the CIP unit and existing syrup room cubicle in AISI 304 stainless steel manufacturing with IP.54 protection degree with auxiliary circuits 24 V Please Note The steam supply piping the steam reduction unit up to 4 bar the system for the recovery and re-launching of the condensate are at Customer Charge A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 15 ANCILLARY SECTION POS.12 N.1 PIPING MATERIAL & IN-HOUSE PRE-ASSEMBLY Piping material suitable to connect the a.m. equipment inside the syrup room built in AISI 316 & AISI 304 stainless steel The set includes pipes fittings valves manual and automatic valves gaskets construction material for piping supporting brackets and everything necessary for the good performance of the plant The processing plant scope of this supply will be in-house pre-assembled pre-wired and pre-tested as follow Ingredients preparation Section (from Pos. 2 to Pos.4) Final beverage preparation Section (from Pos. 4 to Pos.8) N.B.: the pre-assembly between the Cip Unit & the above mentioned section can be quantified & quoted upon receipt of the Lay Out the Plant Will not be in-house pre-assembled pre-wired and pre-tested what follows Washing delivery solution Washing recovery solution Process water Pipeline Loading Lines of all the ingredients from their Storage/Dissolving Tanks up to the Blending Tanks (Position 4 of this Offer) N.B.: in any case can be quantified & quoted upon receipt of the Lay Out the Plant POS.13 N.1 MATERIAL FOR THE ELECTRIC AND PNEUMATIC PLANT Electric material for the connection of the a.m. equipment inside the syrup room The set includes connecting wires stainless steel net cable tray Rilsan pipe electric and pneumatic accessories A DUE SRL OFFER N.0315.13.ML Rev.3 DU 27.03.2013 16 POS.14 N.1 ELECTRIC CONTROL BOARD For the automatic management of the juice processing section including SIEMENS S7 ‘PLC’ electric and pneumatic instruments to control the processing data to control and protect the motors for the signal exchange managing for the integration with the CIP unit and existing syrup room cubicle in AISI 304 stainless steel manufacturing with IP.54 protection degree with auxiliary circuits 24 V Find more here pokazati kontakte Contact us at pokazati kontakte Poruka Poruka